SiC wafer ká áljẹbrà

Silikoni carbide (SiC) wafersti di sobusitireti yiyan fun agbara-giga, igbohunsafẹfẹ-giga, ati ẹrọ itanna iwọn otutu giga kọja ọkọ ayọkẹlẹ, agbara isọdọtun, ati awọn apa afẹfẹ. Portfolio wa ni wiwa awọn polytypes bọtini ati awọn eto doping-nitrogen-doped 4H (4H-N), idabobo ologbele-mimọ giga (HPSI), nitrogen-doped 3C (3C-N), ati p-type 4H / 6H (4H / 6H-P) - ti a funni ni awọn onidiwọn didara mẹta: PRIME tabi didan ti o ni kikun MMY, ẹrọ didan, awọn idanwo ilana), ati Iwadi (awọn ipele apọju aṣa ati awọn profaili doping fun R&D). Awọn iwọn ila opin wafer wa ni iwọn 2 ″, 4″, 6″, 8″, ati 12″ lati ba awọn irinṣẹ pataki mejeeji ati awọn fabs to ti ni ilọsiwaju ba. A tun pese awọn boules monocrystalline ati awọn kirisita irugbin ti o ni iṣalaye ni deede lati ṣe atilẹyin idagbasoke gara inu ile.

Wafers 4H-N ṣe ẹya awọn iwuwo gbigbe lati 1 × 10¹⁶ si 1 × 10¹⁹ cm⁻³ ati awọn resistance ti 0.01–10 Ω·cm, jiṣẹ iṣipopada elekitironi ti o dara julọ ati awọn aaye didenukole loke 2 MV/cm — bojumu fun awọn diodes Schottky, ati awọn MOFETs. Awọn sobusitireti HPSI kọja 1×10¹² Ω·cm resistivity pẹlu awọn iwuwo micropipe ni isalẹ 0.1 cm⁻², ni idaniloju jijo kekere fun RF ati awọn ẹrọ makirowefu. Cubic 3C-N, ti o wa ni awọn ọna kika 2 ″ ati 4 ″, ngbanilaaye heteroepitaxy lori ohun alumọni ati ṣe atilẹyin photonic aramada ati awọn ohun elo MEMS. P-Iru 4H/6H-P wafers, doped pẹlu aluminiomu si 1×10¹⁶–5×10¹⁸ cm⁻³, dẹrọ imudara ẹrọ faaji.

SiC wafer, NOMBA wafers faragba kemikali – mekaniki polishing to <0.2 nm RMS dada roughness, lapapọ sisanra iyatọ labẹ 3 µm, ati teriba <10 µm. Awọn sobusitireti DUMMY yara apejọ ati awọn idanwo iṣakojọpọ, lakoko ti awọn wafers WAA ṣe ẹya awọn sisanra epi-Layer ti 2–30 µm ati doping bespoke. Gbogbo awọn ọja ti ni ifọwọsi nipasẹ ipasẹ X-ray (apata gbigbọn <30 arcsec) ati Raman spectroscopy, pẹlu awọn idanwo itanna — Awọn wiwọn Hall, Profaili C-V, ati ọlọjẹ micropipe — ni idaniloju ibamu JEDEC ati SEMI.

Awọn bolu to 150 mm ni iwọn ila opin ti dagba nipasẹ PVT ati CVD pẹlu awọn iwuwo yiyọ kuro ni isalẹ 1 × 10³ cm⁻² ati awọn iṣiro micropipe kekere. Awọn kirisita irugbin ti ge laarin 0.1 ° ti aaye c-axis lati ṣe iṣeduro idagbasoke atunṣe ati awọn eso gige gige giga.

Nipa apapọ ọpọlọpọ awọn oriṣi polytypes, awọn iyatọ doping, awọn onipò didara, awọn iwọn wafer SiC, ati boule inu ile ati iṣelọpọ irugbin-crystal, Syeed ti sobusitireti SiC wa n ṣatunṣe awọn ẹwọn ipese ati mu idagbasoke ẹrọ pọ si fun awọn ọkọ ina mọnamọna, awọn grids smart, ati awọn ohun elo agbegbe lile.

SiC wafer ká áljẹbrà

Silikoni carbide (SiC) wafersti di sobusitireti SiC ti yiyan fun agbara-giga, igbohunsafẹfẹ-giga, ati ẹrọ itanna iwọn otutu giga kọja ọkọ ayọkẹlẹ, agbara isọdọtun, ati awọn apa afẹfẹ. Portfolio wa ni wiwa awọn oriṣi bọtini ati awọn eto doping-nitrogen-doped 4H (4H-N), idabobo ologbele-mimọ giga (HPSI), nitrogen-doped 3C (3C-N), ati p-type 4H/6H (4H/6H-P) — ti a funni ni awọn onigi didara mẹta: Wafer SiCNOMBA (didan ni kikun, awọn sobusitireti ipele ẹrọ), DUMMY (la tabi ti ko ni didan fun awọn idanwo ilana), ati Iwadi (awọn ipele apọju aṣa ati awọn profaili doping fun R&D). Awọn iwọn ila opin SiC Wafer gigun 2 ″, 4″, 6″, 8″, ati 12″ lati ba awọn irinṣẹ pataki mejeeji ati awọn fabs to ti ni ilọsiwaju mu. A tun pese awọn boules monocrystalline ati awọn kirisita irugbin ti o ni iṣalaye ni deede lati ṣe atilẹyin idagbasoke gara inu ile.

Wafers 4H-N SiC ṣe ẹya iwuwo gbigbe lati 1 × 10¹⁶ si 1 × 10¹⁹ cm⁻³ ati awọn resistance ti 0.01–10 Ω·cm, jiṣẹ iṣipopada elekitironi ti o dara julọ ati awọn aaye didenukole loke 2 MV/cm — bojumu fun Schottky diodes, ati MOSFET. Awọn sobusitireti HPSI kọja 1×10¹² Ω·cm resistivity pẹlu awọn iwuwo micropipe ni isalẹ 0.1 cm⁻², ni idaniloju jijo kekere fun RF ati awọn ẹrọ makirowefu. Cubic 3C-N, ti o wa ni awọn ọna kika 2 ″ ati 4 ″, ngbanilaaye heteroepitaxy lori ohun alumọni ati ṣe atilẹyin photonic aramada ati awọn ohun elo MEMS. SiC wafer P-type 4H/6H-P wafers, doped pẹlu aluminiomu si 1×10¹⁶–5×10¹⁸ cm⁻³, dẹrọ awọn ayaworan ẹrọ ibaramu.

SiC wafer PRIME wafers faragba kemikali – mekaniki polishing to <0.2 nm RMS roughness dada, lapapọ sisanra iyatọ labẹ 3 µm, ati teriba <10 µm. Awọn sobusitireti DUMMY yara apejọ ati awọn idanwo iṣakojọpọ, lakoko ti awọn wafers WAA ṣe ẹya awọn sisanra epi-Layer ti 2–30 µm ati doping bespoke. Gbogbo awọn ọja ti ni ifọwọsi nipasẹ ipasẹ X-ray (apata gbigbọn <30 arcsec) ati Raman spectroscopy, pẹlu awọn idanwo itanna — Awọn wiwọn Hall, Profaili C-V, ati ọlọjẹ micropipe — ni idaniloju ibamu JEDEC ati SEMI.

Awọn bolu to 150 mm ni iwọn ila opin ti dagba nipasẹ PVT ati CVD pẹlu awọn iwuwo yiyọ kuro ni isalẹ 1 × 10³ cm⁻² ati awọn iṣiro micropipe kekere. Awọn kirisita irugbin ti ge laarin 0.1 ° ti aaye c-axis lati ṣe iṣeduro idagbasoke atunṣe ati awọn eso gige gige giga.

Nipa apapọ ọpọlọpọ awọn oriṣi polytypes, awọn iyatọ doping, awọn onipò didara, awọn iwọn wafer SiC, ati boule inu ile ati iṣelọpọ irugbin-crystal, Syeed ti sobusitireti SiC wa n ṣatunṣe awọn ẹwọn ipese ati mu idagbasoke ẹrọ pọ si fun awọn ọkọ ina mọnamọna, awọn grids smart, ati awọn ohun elo agbegbe lile.

6inch 4H-N iru SiC wafer ká data dì

| 6inch SiC wafers data dì | ||||

| Paramita | Iha-Parameter | Z ite | P ite | D ite |

| Iwọn opin | 149,5-150,0 mm | 149,5-150,0 mm | 149,5-150,0 mm | |

| Sisanra | 4H‑N | 350 µm ± 15 µm | 350 µm ± 25 µm | 350 µm ± 25 µm |

| Sisanra | 4H-SI | 500 µm ± 15 µm | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Wafer Iṣalaye | Pa axis: 4.0° si <11-20> ± 0.5° (4H-N); Lori ipo: <0001> ± 0.5° (4H-SI) | Pa axis: 4.0° si <11-20> ± 0.5° (4H-N); Lori ipo: <0001> ± 0.5° (4H-SI) | Pa axis: 4.0° si <11-20> ± 0.5° (4H-N); Lori ipo: <0001> ± 0.5° (4H-SI) | |

| Iwuwo Micropipe | 4H‑N | 0.2 cm⁻² | ≤2 cm⁻² | ≤ 15 cm⁻² |

| Iwuwo Micropipe | 4H-SI | ≤ 1 cm⁻² | ≤ 5 cm⁻² | ≤ 15 cm⁻² |

| Resistivity | 4H‑N | 0.015–0.024 Ω · cm | 0.015–0.028 Ω·cm | 0.015–0.028 Ω·cm |

| Resistivity | 4H-SI | 1×10¹⁰ Ω·cm | 1×10⁵ Ω·cm | |

| Primary Flat Iṣalaye | [10-10] ± 5.0 ° | [10-10] ± 5.0 ° | [10-10] ± 5.0 ° | |

| Primary Flat Gigun | 4H‑N | 47,5 mm ± 2,0 mm | ||

| Primary Flat Gigun | 4H-SI | Ogbontarigi | ||

| Iyasoto eti | 3 mm | |||

| Warp/LTV/TTV/Tẹriba | ≤2.5 µm / ≤6 µm / ≤25 µm / ≤35 µm | ≤5 µm / ≤15 µm / ≤40 µm / ≤60 µm | ||

| Irora | pólándì | Ra ≤ 1 nm | ||

| Irora | CMP | Ra ≤ 0.2 nm | Ra ≤ 0.5 nm | |

| Awọn dojuijako eti | Ko si | Ipari ipari ≤ 20 mm, ẹyọkan ≤ 2 mm | ||

| Hex farahan | Agbegbe akojọpọ ≤ 0.05% | Agbegbe akojọpọ ≤ 0.1% | Agbegbe akojọpọ ≤ 1% | |

| Awọn agbegbe Polytype | Ko si | Agbegbe akojọpọ ≤ 3% | Agbegbe akojọpọ ≤ 3% | |

| Erogba Ifisi | Agbegbe akojọpọ ≤ 0.05% | Agbegbe akojọpọ ≤ 3% | ||

| Dada Scratches | Ko si | Igi gigun ≤ 1 × iwọn ila opin wafer | ||

| Awọn eerun eti | Ko si idasilẹ ≥ 0.2 mm iwọn & ijinle | Titi di awọn eerun 7, ≤ 1 mm kọọkan | ||

| TSD (Yíyọ skru Skru) | ≤ 500 cm⁻² | N/A | ||

| BPD (Idipa Ọkọ ofurufu Ipilẹ) | ≤ 1000 cm⁻² | N/A | ||

| Idoti Dada | Ko si | |||

| Iṣakojọpọ | Kasẹti-wafer pupọ tabi eiyan wafer ẹyọkan | Kasẹti-wafer pupọ tabi eiyan wafer ẹyọkan | Kasẹti-wafer pupọ tabi eiyan wafer ẹyọkan | |

4inch 4H-N iru SiC wafer ká data dì

| 4inch SiC wafer ká data dì | |||

| Paramita | Odo MPD Production | Didara Iṣe Iṣejade (Ite P) | Idiwon Ite (D ite) |

| Iwọn opin | 99,5 mm-100,0 mm | ||

| Sisanra (4H-N) | 350 µm± 15 µm | 350 µm± 25 µm | |

| Sisanra (4H-Si) | 500 µm± 15 µm | 500 µm± 25 µm | |

| Wafer Iṣalaye | Pa axis: 4.0 ° si <1120> ± 0.5 ° fun 4H-N; Lori ipo: <0001> ± 0.5 ° fun 4H-Si | ||

| Ìwúwo Micropipe (4H-N) | ≤0.2 cm⁻² | ≤2 cm⁻² | ≤15 cm⁻² |

| Ìwúwo Micropipe (4H-Si) | ≤1 cm⁻² | ≤5 cm⁻² | ≤15 cm⁻² |

| Atako (4H-N) | 0.015–0.024 Ω · cm | 0.015–0.028 Ω·cm | |

| Resistivity (4H-Si) | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |

| Primary Flat Iṣalaye | [10-10] ± 5.0 ° | ||

| Primary Flat Gigun | 32,5 mm ± 2,0 mm | ||

| Secondary Flat Gigun | 18,0 mm ± 2,0 mm | ||

| Atẹle Flat Iṣalaye | Silikoni koju soke: 90 ° CW lati alapin akọkọ ± 5.0 ° | ||

| Iyasoto eti | 3 mm | ||

| LTV / TTV / Teriba Warp | ≤2.5 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| Irora | Polish Ra ≤1 nm; CMP Ra ≤0.2 nm | Ra ≤0.5 nm | |

| Eti dojuijako Nipa Ga kikankikan Light | Ko si | Ko si | Ipari ipari ≤10 mm; nikan ipari ≤2 mm |

| Hex farahan Nipa High kikankikan Light | Agbegbe akojọpọ ≤0.05% | Agbegbe akojọpọ ≤0.05% | Agbegbe akojọpọ ≤0.1% |

| Awọn agbegbe Polytype Nipa Imọlẹ Kikan Giga | Ko si | Agbegbe akojọpọ ≤3% | |

| Visual Erogba Ifisi | Agbegbe akojọpọ ≤0.05% | Agbegbe akojọpọ ≤3% | |

| Silicon Surface Scratches Nipa Giga kikankikan Light | Ko si | Akopọ ipari ≤1 iwọn ila opin wafer | |

| Awọn eerun eti Nipa Imọlẹ Imọlẹ giga | Ko si idasilẹ ≥0.2 mm fifẹ ati ijinle | 5 laaye, ≤1 mm kọọkan | |

| Ohun alumọni dada kontaminesonu Nipa High kikankikan Light | Ko si | ||

| Threading dabaru dislocation | ≤500 cm⁻² | N/A | |

| Iṣakojọpọ | Kasẹti-wafer pupọ tabi eiyan wafer ẹyọkan | Kasẹti-wafer pupọ tabi eiyan wafer ẹyọkan | Kasẹti-wafer pupọ tabi eiyan wafer ẹyọkan |

4inch HPSI iru SiC wafer ká data dì

| 4inch HPSI iru SiC wafer ká data dì | |||

| Paramita | Odo MPD Itejade (Ipele Z) | Didara Iṣe Iṣejade (Ite P) | Idiwon Ite (D ite) |

| Iwọn opin | 99.5-100.0 mm | ||

| Sisanra (4H-Si) | 500 µm ± 20 µm | 500 µm ± 25 µm | |

| Wafer Iṣalaye | Pa axis: 4.0 ° si <11-20> ± 0.5 ° fun 4H-N; Lori ipo: <0001> ± 0.5 ° fun 4H-Si | ||

| Ìwúwo Micropipe (4H-Si) | ≤1 cm⁻² | ≤5 cm⁻² | ≤15 cm⁻² |

| Resistivity (4H-Si) | ≥1E9 Ω·cm | ≥1E5 Ω·cm | |

| Primary Flat Iṣalaye | (10-10) ± 5,0 ° | ||

| Primary Flat Gigun | 32,5 mm ± 2,0 mm | ||

| Secondary Flat Gigun | 18,0 mm ± 2,0 mm | ||

| Atẹle Flat Iṣalaye | Silikoni koju soke: 90 ° CW lati alapin akọkọ ± 5.0 ° | ||

| Iyasoto eti | 3 mm | ||

| LTV / TTV / Teriba Warp | ≤3 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| Irora (oju C) | pólándì | Ra ≤1 nm | |

| Irora (oju Si) | CMP | Ra ≤0.2 nm | Ra ≤0.5 nm |

| Eti dojuijako Nipa Ga kikankikan Light | Ko si | Ipari ipari ≤10 mm; nikan ipari ≤2 mm | |

| Hex farahan Nipa High kikankikan Light | Agbegbe akojọpọ ≤0.05% | Agbegbe akojọpọ ≤0.05% | Agbegbe akojọpọ ≤0.1% |

| Awọn agbegbe Polytype Nipa Imọlẹ Kikan Giga | Ko si | Agbegbe akojọpọ ≤3% | |

| Visual Erogba Ifisi | Agbegbe akojọpọ ≤0.05% | Agbegbe akojọpọ ≤3% | |

| Silicon Surface Scratches Nipa Giga kikankikan Light | Ko si | Akopọ ipari ≤1 iwọn ila opin wafer | |

| Awọn eerun eti Nipa Imọlẹ Imọlẹ giga | Ko si idasilẹ ≥0.2 mm fifẹ ati ijinle | 5 laaye, ≤1 mm kọọkan | |

| Ohun alumọni dada kontaminesonu Nipa High kikankikan Light | Ko si | Ko si | |

| Threading dabaru Dislocation | ≤500 cm⁻² | N/A | |

| Iṣakojọpọ | Kasẹti-wafer pupọ tabi eiyan wafer ẹyọkan | ||

SiC wafer ká ohun elo

-

Awọn modulu Agbara SiC Wafer fun Awọn oluyipada EV

Awọn MOSFET ti o da lori wafer SiC ati awọn diodes ti a ṣe lori awọn sobusitireti SiC wafer ti o ga julọ ṣafipamọ awọn adanu iyipada-kekere. Nipa lilo imọ-ẹrọ wafer SiC, awọn modulu agbara wọnyi ṣiṣẹ ni awọn foliteji ti o ga ati awọn iwọn otutu, ti n mu awọn oluyipada isunki daradara diẹ sii. Ṣiṣepọ SiC wafer ku sinu awọn ipele agbara dinku awọn ibeere itutu agbaiye ati ifẹsẹtẹ, ti n ṣe afihan agbara kikun ti isọdọtun wafer SiC. -

Igbohunsafẹfẹ RF & Awọn ẹrọ 5G lori SiC Wafer

Awọn ampilifaya RF ati awọn iyipada ti a ṣe lori awọn iru ẹrọ SiC wafer ologbele-idabobo ṣe afihan adaṣe igbona giga ati foliteji didenukole. Sobusitireti SiC wafer dinku awọn ipadanu dielectric ni awọn igbohunsafẹfẹ GHz, lakoko ti agbara ohun elo SiC wafer ngbanilaaye fun iṣẹ iduroṣinṣin labẹ agbara giga, awọn ipo iwọn otutu - ṣiṣe SiC wafer ni sobusitireti yiyan fun atẹle-gen 5G awọn ibudo ipilẹ ati awọn eto radar. -

Optoelectronic & Awọn sobsitireti LED lati SiC Wafer

Awọn LED buluu ati UV ti o dagba lori awọn sobusitireti wafer SiC ni anfani lati ibaamu lattice ti o dara julọ ati itusilẹ ooru. Lilo wafer C-face SiC didan ṣe idaniloju awọn fẹlẹfẹlẹ epitaxial aṣọ, lakoko ti lile atorunwa ti wafer SiC n jẹ ki o tinrin tinrin daradara ati apoti ohun elo igbẹkẹle. Eyi jẹ ki SiC wafer jẹ go-si pẹpẹ fun agbara-giga, awọn ohun elo LED igbesi aye gigun.

SiC wafer ká Q&A

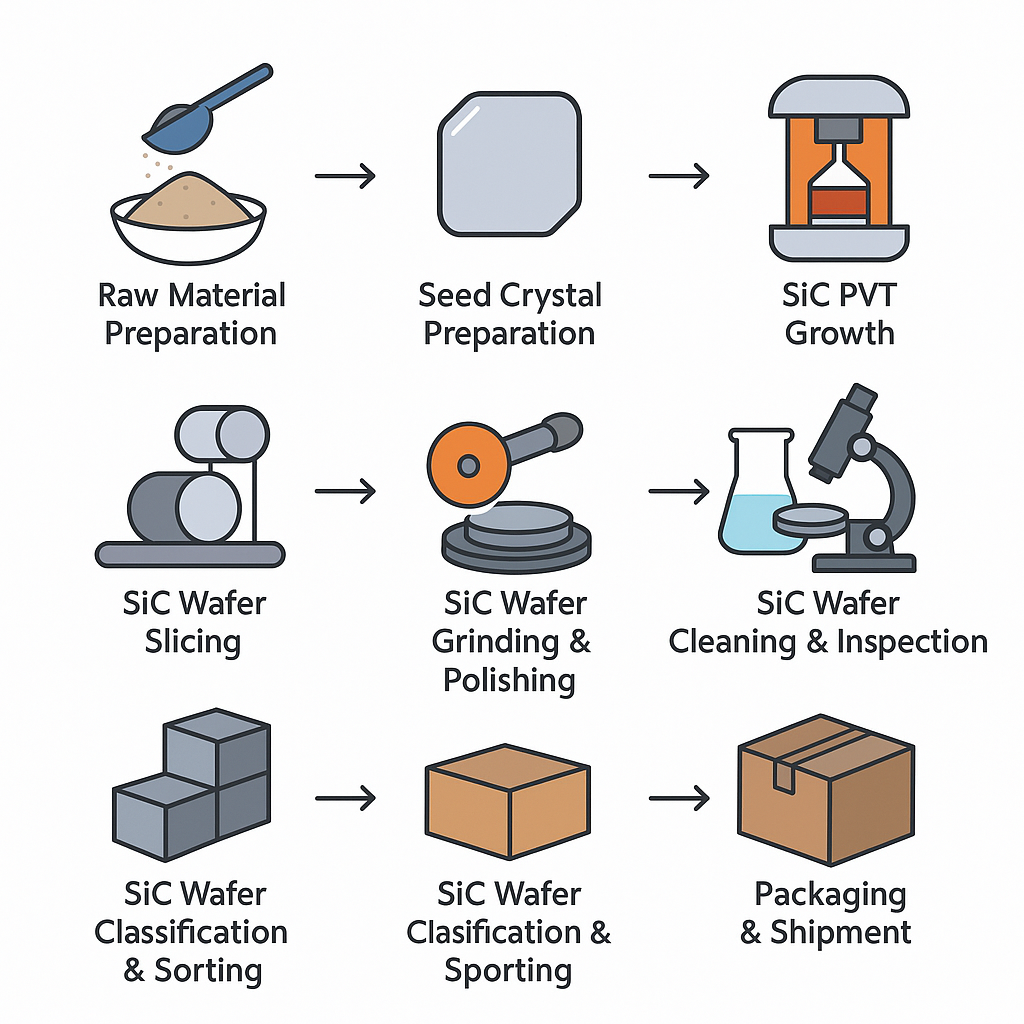

1. Q: Bawo ni awọn wafers SiC ṣe ṣelọpọ?

A:

SiC wafers ti ṣelọpọAwọn Igbesẹ Alaye

-

SiC wafersIgbaradi Ohun elo Aise

- Lo ≥5N-ite SiC lulú (awọn aimọ ≤1 ppm).

- Sieve ati ṣaju-bere lati yọkuro erogba ti o ku tabi awọn agbo ogun nitrogen.

-

SiCIrugbin Crystal Igbaradi

-

Mu nkan kan ti 4H-SiC kristali kan, ge pẹlu iṣalaye 〈0001〉 si ~10 × 10 mm².

-

Pólándì tó péye sí Ra ≤0.1 nm àti àmì ìṣàlaye kirisita.

-

-

SiCÌdàgbàsókè PVT (Ọkọ Òru Ti Ti ara)

-

Fifuye lẹẹdi crucible: isalẹ pẹlu SiC lulú, oke pẹlu irugbin gara.

-

Jade lọ si 10⁻³–10⁻ Torr tabi fikun-pada pẹlu helium mimọ-giga ni 1 atm.

-

Agbegbe orisun ooru si 2100-2300 ℃, ṣetọju agbegbe irugbin 100-150 ℃ kula.

-

Ṣakoso oṣuwọn idagbasoke ni 1-5 mm / h lati dọgbadọgba didara ati gbigbejade.

-

-

SiCIngot Annealing

-

Pa ingot SiC ti o dagba ni 1600–1800 ℃ fun wakati 4–8.

-

Idi: yọkuro awọn aapọn igbona ati dinku iwuwo dislocation.

-

-

SiCWafer Bibẹ

-

Lo okun waya diamond kan lati ge ingot sinu awọn wafer ti o nipọn 0.5-1 mm.

-

Din gbigbọn ati agbara ita lati yago fun awọn dojuijako bulọọgi.

-

-

SiCWaferLilọ & didan

-

Isokuso lilọlati yọkuro bibajẹ sawing (ainira ~ 10-30 µm).

-

Fine lilọlati se aseyori flatness ≤5 µm.

-

Dindan-Ẹrọ-Kẹmika (CMP)lati de ipari bi digi (Ra ≤0.2 nm).

-

-

SiCWaferNinu & Ayewo

-

Ultrasonic ninuni ojutu Piranha (H₂SO₄: H₂O₂), omi DI, lẹhinna IPA.

-

XRD/Raman spectroscopylati jẹrisi polytype (4H, 6H, 3C).

-

Interferometrylati wiwọn flatness (<5 µm) ati ija (<20 µm).

-

Iwadii-ojuami mẹrinlati ṣe idanwo resistivity (fun apẹẹrẹ HPSI ≥10⁹ Ω·cm).

-

Ayẹwo abawọnlabẹ polarized ina maikirosikopu ati ibere tester.

-

-

SiCWaferIsọri & Tito lẹsẹsẹ

-

To awọn wafers nipasẹ polytype ati iru itanna:

-

4H-SiC N-Iru (4H-N): ifọkansi ti ngbe 10¹⁶–10¹⁸ cm⁻³

-

4H-SiC High Purity Semi-Insulating (4H-HPSI): resistivity ≥10⁹ Ω·cm

-

6H-SiC N-iru (6H-N)

-

Awọn miiran: 3C-SiC, P-type, ati bẹbẹ lọ.

-

-

-

SiCWaferIṣakojọpọ & Gbigbe

2. Q: Kini awọn anfani bọtini ti SiC wafers lori awọn ohun alumọni siliki?

A: Ti a ṣe afiwe si awọn wafer silikoni, awọn wafers SiC ṣiṣẹ:

-

Ti o ga foliteji isẹ(> 1,200 V) pẹlu kekere on-resistance.

-

Iduroṣinṣin iwọn otutu ti o ga julọ(> 300 °C) ati ilọsiwaju iṣakoso igbona.

-

Yiyara yipada awọn iyarapẹlu awọn adanu iyipada kekere, idinku itutu-ipele eto ati iwọn ni awọn oluyipada agbara.

4. Q: Awọn abawọn ti o wọpọ wo ni ipa SiC wafer ikore ati iṣẹ?

A: Awọn abawọn akọkọ ni awọn wafers SiC pẹlu awọn micropipes, awọn dislocations basal ofurufu (BPDs), ati awọn oju oju. Awọn micropipes le fa ikuna ẹrọ ajalu; Awọn BPD pọ si-resistance lori akoko; ati awọn scratches dada ja si wafer breakage tabi ko dara epitaxial idagbasoke. Ṣiṣayẹwo lile ati idinku abawọn jẹ pataki lati mu iwọn wafer SiC pọ si.

Akoko ifiweranṣẹ: Jun-30-2025