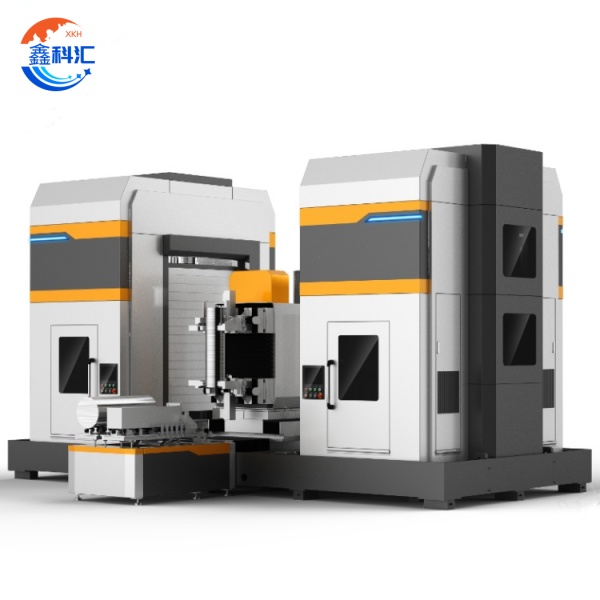

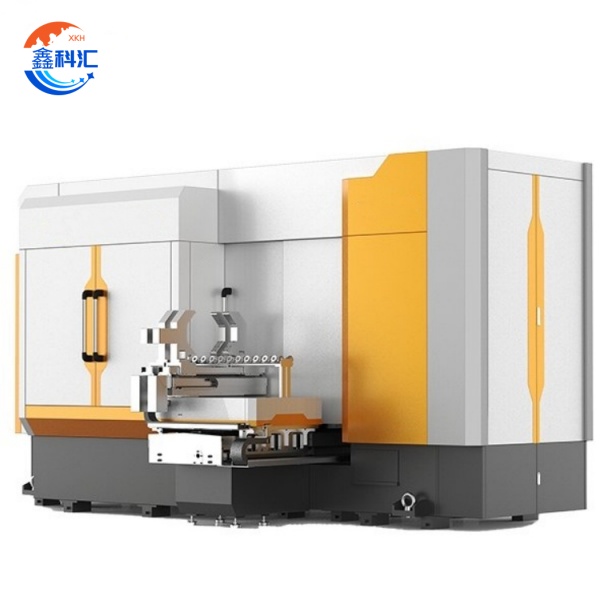

Double station square ẹrọ monocrystalline silikoni opa processing 6/8/12 inch dada flatness Ra≤0.5μm

Awọn ẹya ara ẹrọ:

(1) Double station amuṣiṣẹpọ

· Iṣiṣẹ meji: Ṣiṣe nigbakanna ti awọn ọpa ohun alumọni meji (Ø6 "-12") mu iṣẹ-ṣiṣe pọ si nipasẹ 40% -60% vs. Simplex ẹrọ.

· Iṣakoso ominira: Ibusọ kọọkan le ṣatunṣe ominira ni ominira awọn aye gige (ẹdọfu, iyara kikọ sii) lati ni ibamu si awọn pato ọpa ohun alumọni oriṣiriṣi.

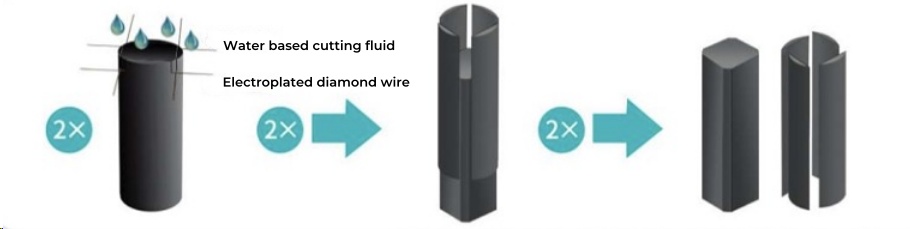

(2) Gige-konge Ige

· Ipeye iwọn: square bar ẹgbẹ ijinna ifarada ± 0.15mm, ibiti o ≤0.20mm.

· Didara oju: gige gige fifọ <0.5mm, dinku iye lilọ atẹle.

(3) Iṣakoso oye

· Ige adaṣe: ibojuwo akoko gidi ti ohun alumọni opa ohun alumọni, atunṣe agbara ti ọna gige (gẹgẹbi sisẹ ọpa ohun alumọni ti o tẹ).

· Kakiri data: ṣe igbasilẹ awọn aye ṣiṣe ti ọpa ohun alumọni kọọkan lati ṣe atilẹyin docking eto MES.

(4) Iye owo agbara kekere

· Lilo okun waya Diamond: ≤0.06m/mm (ipari opa silikoni), iwọn ila opin waya ≤0.30mm.

· Itumọ itutu: Eto sisẹ fa igbesi aye iṣẹ pọ si ati dinku isọnu omi egbin.

Imọ-ẹrọ ati awọn anfani idagbasoke:

(1) Imudara imọ-ẹrọ gige

- Ige ila-pupọ: 100-200 awọn ila diamond ni a lo ni afiwe, ati iyara gige jẹ ≥40mm / min.

- Iṣakoso ẹdọfu: Titiipa eto atunṣe loop (± 1N) lati dinku eewu ti fifọ waya.

(2) Ifaagun ibamu

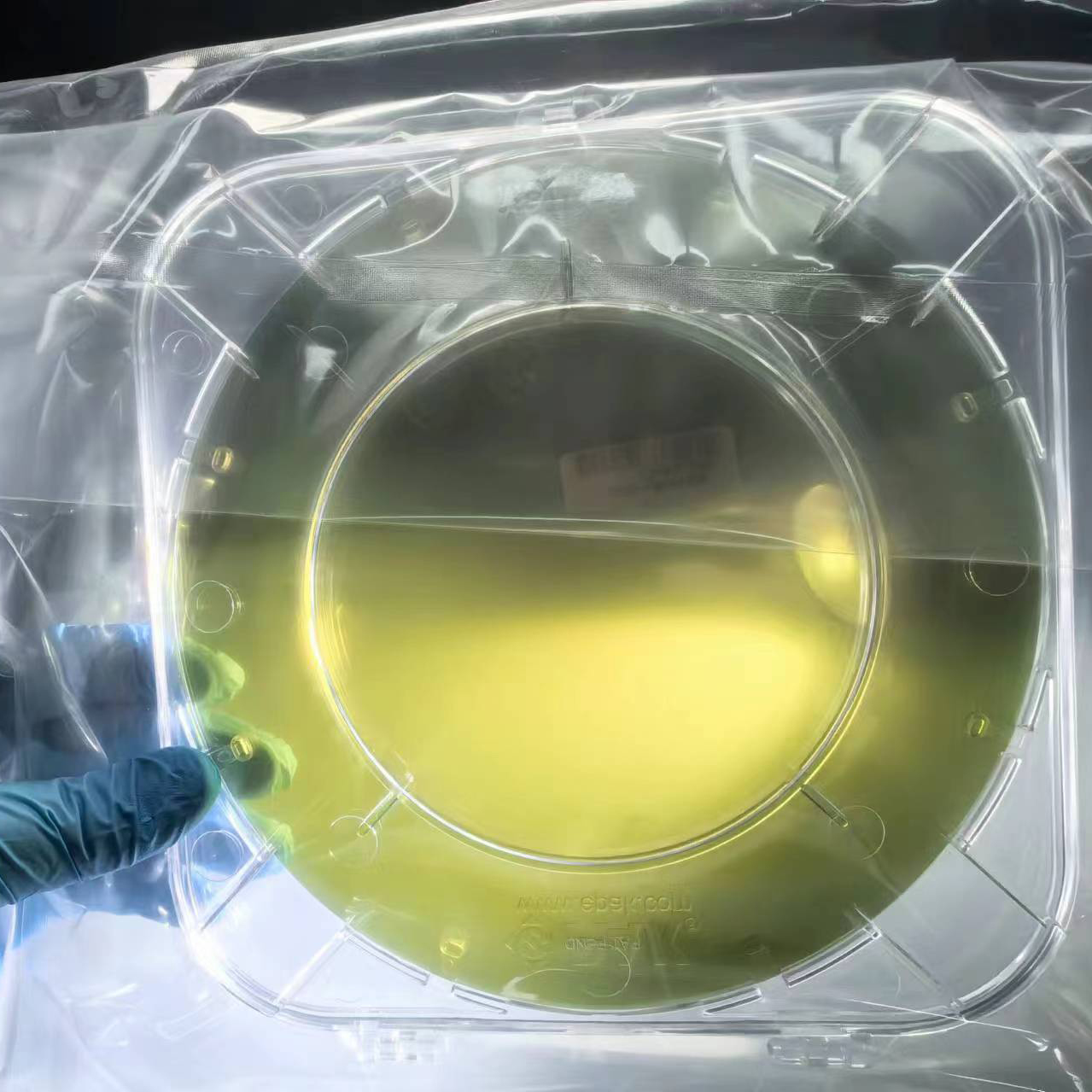

- Aṣamubadọgba ohun elo: Atilẹyin P-type / N-type monocrystalline silikoni, ni ibamu pẹlu TOPCon, HJT ati awọn ọpa ohun alumọni batiri ti o ga julọ.

- Rọ iwọn: ohun alumọni opa ipari 100-950mm, square opa ẹgbẹ ijinna 166-233mm adijositabulu.

(3) Automation igbesoke

- Ikojọpọ ati ikojọpọ robot: ikojọpọ laifọwọyi / ikojọpọ awọn ọpa ohun alumọni, lu awọn iṣẹju ≤3.

- Awọn iwadii oye: itọju asọtẹlẹ lati dinku akoko isunmọ ti a ko gbero.

(4) ile ise olori

- Atilẹyin Wafer: le ṣe ilana ≥100μm ohun alumọni ultra-tinrin pẹlu awọn ọpa onigun mẹrin, oṣuwọn pipin <0.5%.

- Imudara agbara agbara: Lilo agbara fun ẹyọkan ti ọpa ohun alumọni ti dinku nipasẹ 30% (la pẹlu ohun elo ibile).

Awọn paramita imọ-ẹrọ:

| Orukọ paramita | Atọka iye |

| Nọmba ti ifi ilọsiwaju | 2 ege / ṣeto |

| Ilana ipari ipari igi | 100 ~ 950mm |

| Machining ala ibiti | 166-233mm |

| Iyara gige | ≥40mm/min |

| Diamond waya iyara | 0 ~ 35m/s |

| Diamond opin | 0,30 mm tabi kere si |

| Lilo laini | 0.06 m / mm tabi kere si |

| Ibamu yika ọpá opin | Ti pari iwọn ila opin ọpa onigun mẹrin +2mm, Rii daju oṣuwọn didi didan |

| Ige eti breakage Iṣakoso | Aise eti ≤0.5mm, Ko si chipping, ga dada didara |

| Arc ipari uniformity | Iwọn asọtẹlẹ <1.5mm, Ayafi fun iparun opa silikoni |

| Iwọn ẹrọ (Ẹrọ ẹyọkan) | 4800× 3020×3660mm |

| Lapapọ agbara won won | 56kW |

| Òkú àdánù ti ẹrọ | 12t |

Tabili atọka išedede ẹrọ:

| Ohun kan konge | Ibiti ifarada |

| Square bar alafo ifarada | ± 0.15mm |

| Square bar eti ibiti | ≤0.20mm |

| Igun lori gbogbo awọn ẹgbẹ ti square ọpá | 90°±0.05° |

| Flatness ti square ọpá | ≤0.15mm |

| Robot tun ipo išedede | ± 0.05mm |

Awọn iṣẹ XKH:

XKH n pese awọn iṣẹ ti o ni kikun fun awọn ẹrọ ibudo meji-oṣuwọn ohun alumọni mono-crystalline, pẹlu isọdi ohun elo (ibaramu pẹlu awọn ọpa ohun alumọni nla), fifisilẹ ilana (pipe paramita ti o dara ju), ikẹkọ iṣiṣẹ ati atilẹyin lẹhin-tita (ipese awọn ẹya bọtini, ayẹwo idanimọ latọna jijin), ni idaniloju pe awọn alabara ṣaṣeyọri ikore giga (> 99%) ati iṣelọpọ idiyele idiyele kekere, ati pese gige gige imọ-ẹrọ (bii). Akoko ifijiṣẹ jẹ oṣu 2-4.

Alaye aworan atọka