Ion Beam Polishing Machine fun oniyebiye SiC Si

Alaye aworan atọka

Ọja Akopọ ti Ion tan ina polishing Machine

Ion Beam Figuring ati ẹrọ didan da lori ilana ti sputtering ion. Ninu iyẹwu igbale ti o ga, orisun ion kan n ṣe pilasima, eyiti o jẹ iyara sinu ina ion agbara-giga. Tan ina yi bombards dada ti paati opiti, yiyọ ohun elo kuro ni iwọn atomiki lati ṣaṣeyọri atunse oju-aye pipe ati ipari.

Gẹgẹbi ilana ti kii ṣe olubasọrọ, ion beam polishing yọkuro aapọn ẹrọ ati yago fun ibajẹ abẹlẹ, ti o jẹ ki o jẹ apẹrẹ fun iṣelọpọ awọn opiti giga-giga ti a lo ninu astronomy, aerospace, semiconductors, ati awọn ohun elo iwadii ilọsiwaju.

Ilana Ṣiṣẹ ti Ion Beam Polishing Machine

Ion Iran

Gaasi inert (fun apẹẹrẹ, argon) ti ṣe sinu iyẹwu igbale ati ionized nipasẹ itusilẹ itanna lati ṣe pilasima.

Isare & Ibiyi tan ina

Awọn ions ti wa ni onikiakia si ọpọlọpọ awọn ọgọrun tabi ẹgbẹrun elekitironi volts (eV) ati ki o ṣe apẹrẹ sinu iduro, aaye tan ina idojukọ.

Yiyọ ohun elo

Tan ina ion ni ti ara sputers awọn ọta lati dada lai pilẹṣẹ kemikali aati.

Wiwa aṣiṣe & Eto Ilana

Awọn iyapa eeya oju oju jẹ iwọn pẹlu interferometry. Awọn iṣẹ yiyọ kuro ni a lo lati pinnu awọn akoko gbigbe ati ṣe agbekalẹ awọn ipa-ọna irinṣẹ iṣapeye.

Atunse Lupu-pipade

Awọn iyika aṣetunṣe ti sisẹ ati wiwọn tẹsiwaju titi awọn ibi-afẹde deede RMS/PV yoo waye.

Key Awọn ẹya ara ẹrọ ti Ion tan ina polishing Machine

Ibamu dada gbogbo- Awọn ilana alapin, iyipo, aspherical, ati awọn oju-ọna ọfẹ

Ultra-idurosinsin Rate yiyọ– Mu ṣiṣẹ atunse olusin sub-nanometer

Bibajẹ-Free Processing- Ko si awọn abawọn subsurface tabi awọn ayipada igbekale

Dédé Performance- Ṣiṣẹ ni deede daradara lori awọn ohun elo ti lile lile

Atunse Igbohunsafẹfẹ Kekere / Alabọde- Imukuro awọn aṣiṣe laisi ipilẹṣẹ agbedemeji / awọn ohun elo igbohunsafẹfẹ giga

Ibeere Itọju Kekere– Gigun lemọlemọfún isẹ ti pẹlu pọọku downtime

Main Technical pato ti Ion tan ina polishing Machine

| Nkan | Sipesifikesonu |

| Ilana Ilana | Ion sputtering ni a ga-igbale ayika |

| Ilana Ṣiṣe | Non-olubasọrọ dada figuring & didan |

| Max Workpiece Iwon | Φ4000 mm |

| Awọn ẹdun išipopada | 3-ipo / 5-apa |

| Iduroṣinṣin Yiyọ | ≥95% |

| Dada Yiye | PV <10 nm; RMS ≤ 0.5 nm (aṣoju RMS <1 nm; PV <15 nm) |

| Agbara Atunse Igbohunsafẹfẹ | Yọ awọn aṣiṣe igbohunsafẹfẹ alabọde kuro lai ṣe afihan awọn aṣiṣe aarin/giga |

| Isẹ ti o tẹsiwaju | Awọn ọsẹ 3-5 laisi itọju igbale |

| Iye owo itọju | Kekere |

Processing Agbara ti Ion tan ina polishing Machine

Atilẹyin dada Orisi

Rọrun: Alapin, iyipo, prism

Complex: Symmetric/asymmetric asphere, pa-axis asphere, cylindrical

Akanse: Awọn opiti tinrin, awọn opiti slat, awọn opiti hemispherical, awọn opiti conformal, awọn awo alakoso, awọn roboto ọfẹ

Awọn ohun elo atilẹyin

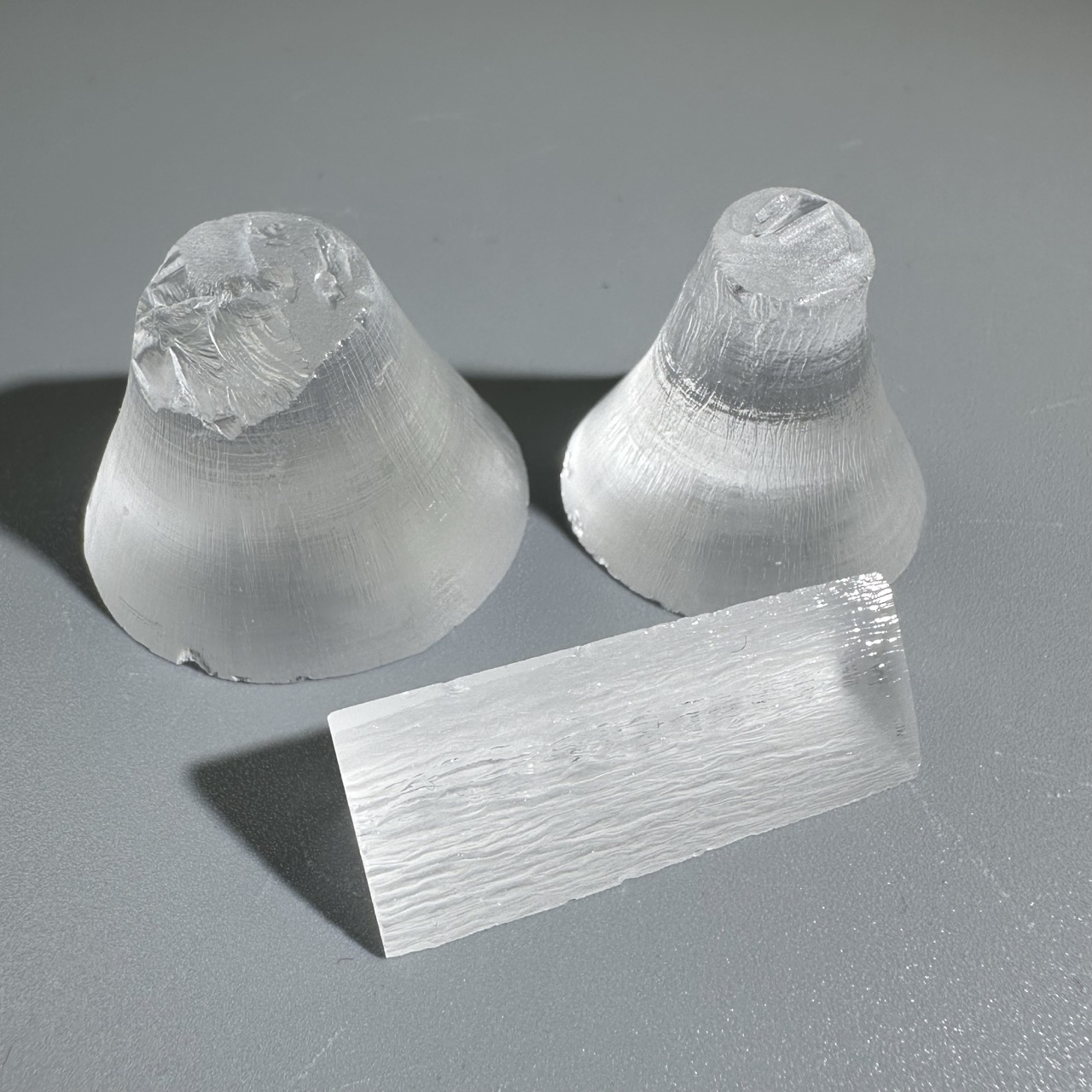

Gilasi opitika: Quartz, microcrystalline, K9, ati bẹbẹ lọ.

Awọn ohun elo infurarẹẹdi: Silikoni, germanium, ati bẹbẹ lọ.

Awọn irin: Aluminiomu, irin alagbara, irin alloy titanium, bbl

Awọn kirisita: YAG, carbide silikoni-orin, ati bẹbẹ lọ.

Awọn ohun elo lile / brittle: Silicon carbide, ati bẹbẹ lọ.

Dada Quality / konge

PV <10 nm

RMS ≤ 0.5 nm

Processing Case Studies of Ion tan ina polishing Machine

irú 1 - Standard Flat Mirror

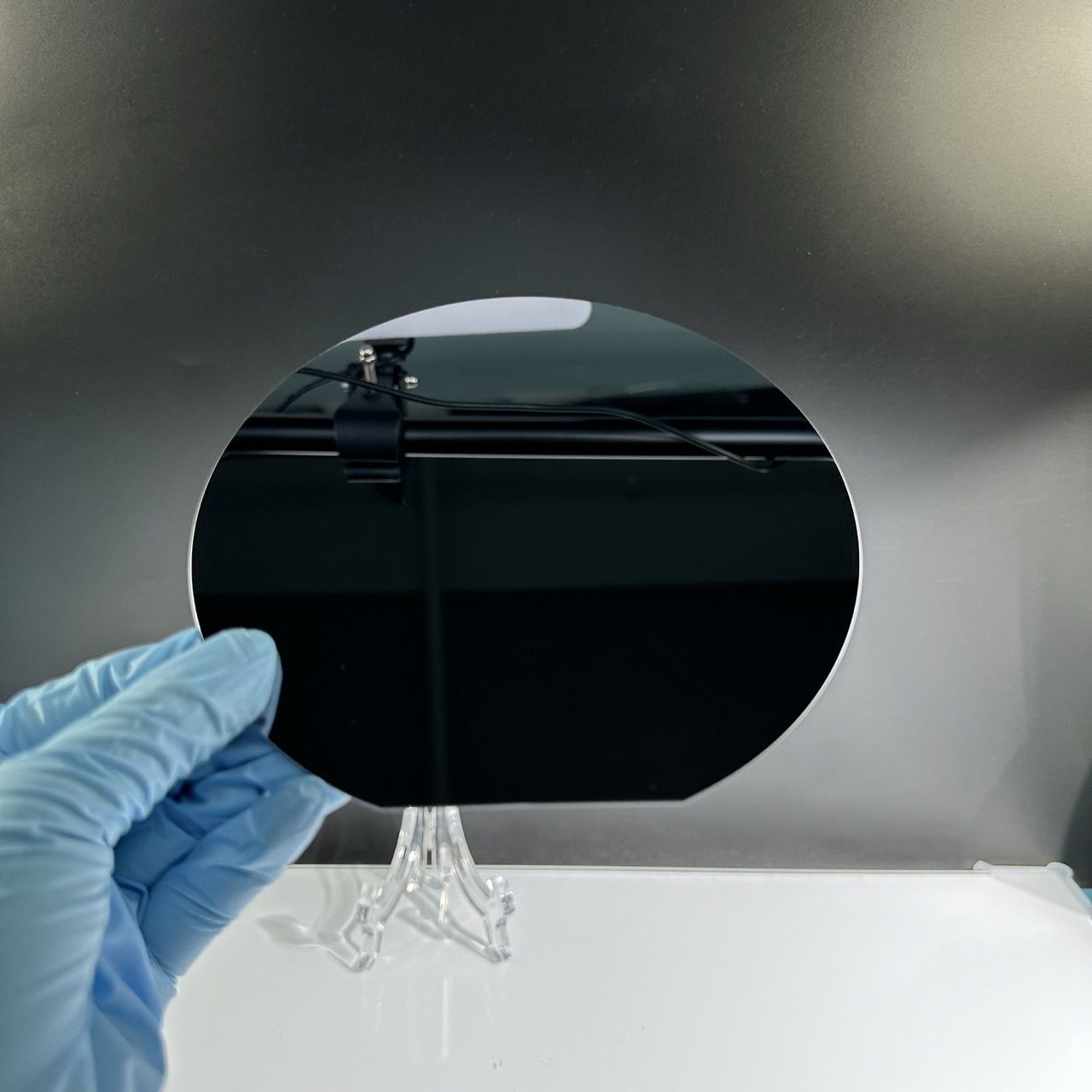

Workpiece: D630 mm kuotisi alapin

Abajade: PV 46.4 nm; RMS 4,63 nm

Case 2 - X-ray Reflective Mirror

Iṣẹ iṣẹ: 150 × 30 mm silikoni alapin

Abajade: PV 8.3 nm; RMS 0.379 nm; Ite 0.13 µrad

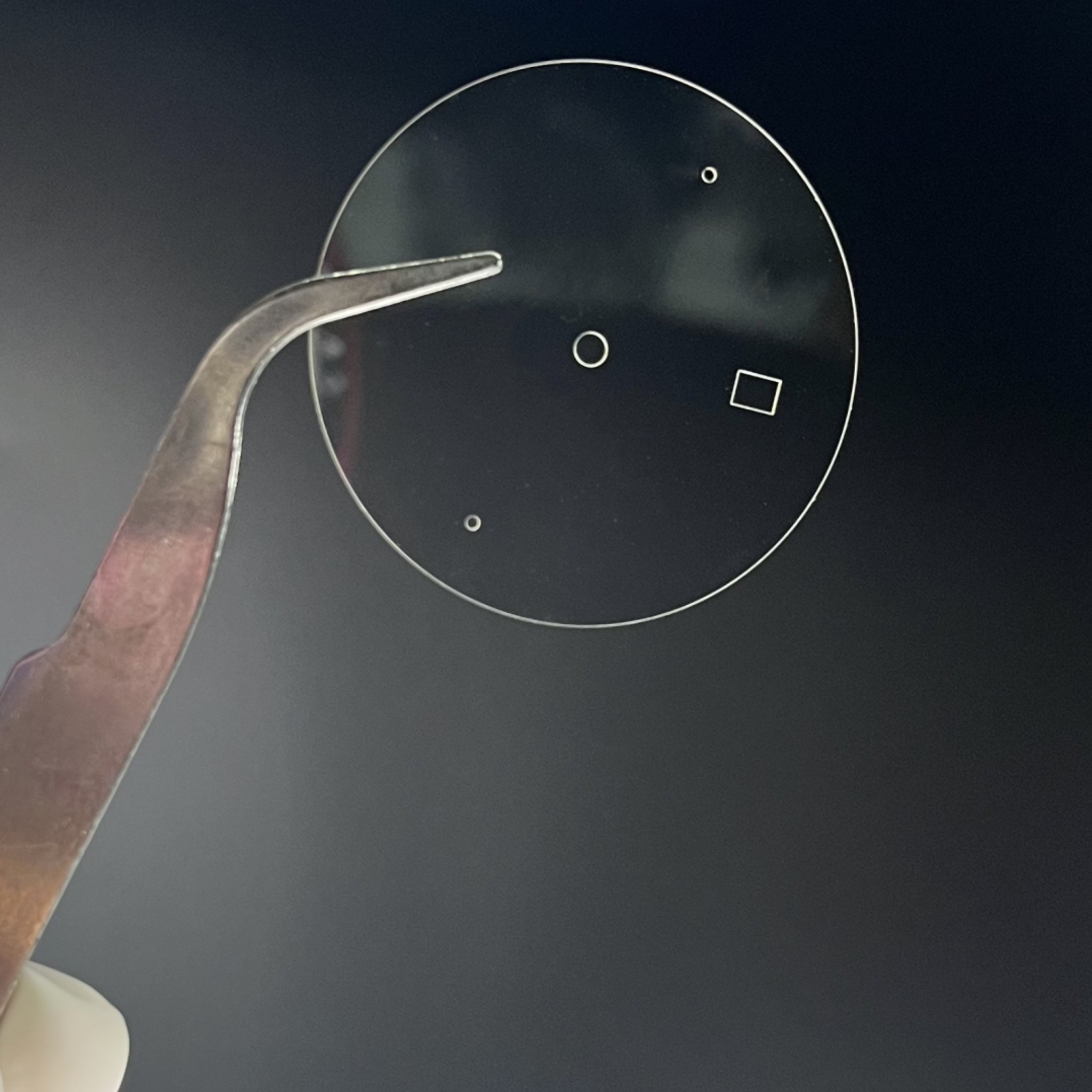

Case 3 - Pa-Axis Mirror

Workpiece: D326 mm pa-apa ilẹ digi

Abajade: PV 35.9 nm; RMS 3,9 nm

FAQ ti awọn gilaasi kuotisi

FAQ – Ion tan ina polishing Machine

Q1: Kini ion beam polishing?

A1:Ion beam polishing jẹ ilana ti kii ṣe olubasọrọ ti o nlo ina ti a dojukọ ti awọn ions (gẹgẹbi awọn ions argon) lati yọ ohun elo kuro ni oju-iṣẹ iṣẹ. Awọn ions ti wa ni onikiakia ati itọsọna si oju, nfa yiyọ ohun elo ipele atomiki, ti o yọrisi awọn ipari ni didan. Ilana yii ṣe imukuro aapọn ẹrọ ati ibajẹ subsurface, ti o jẹ ki o jẹ apẹrẹ fun awọn paati opiti deede.

Q2: Iru awọn ipele wo le ṣe ilana Ion Beam Polishing Machine?

A2:AwọnIon tan ina polishing Machinele lọwọ orisirisi awọn roboto, pẹlu o rọrun opitika irinše biawọn ile adagbe, awọn aaye, ati awọn prisms, bi daradara bi eka geometries biaspheres, pa-ipo aspheres, atifreeform roboto. O munadoko paapaa lori awọn ohun elo bii gilasi opiti, awọn opiti infurarẹẹdi, awọn irin, ati awọn ohun elo lile/brittle.

Q3: Awọn ohun elo wo ni Ion Beam Polishing Machine le ṣiṣẹ pẹlu?

A3:AwọnIon tan ina polishing Machinele ṣe didan ọpọlọpọ awọn ohun elo, pẹlu:

-

gilasi opitika: kuotisi, microcrystalline, K9, ati be be lo.

-

Awọn ohun elo infurarẹẹdi: Silikoni, germanium, ati bẹbẹ lọ.

-

Awọn irin: Aluminiomu, irin alagbara, irin, titanium alloy, ati be be lo.

-

Awọn ohun elo Crystal: YAG, silikoni carbide ẹyọkan, ati bẹbẹ lọ.

-

Miiran lile / brittle ohun elo: Silikoni carbide, ati be be lo.

Nipa re

XKH ṣe amọja ni idagbasoke imọ-ẹrọ giga, iṣelọpọ, ati tita ti gilasi opiti pataki ati awọn ohun elo gara titun. Awọn ọja wa ṣe iranṣẹ ẹrọ itanna opiti, ẹrọ itanna olumulo, ati ologun. A nfun awọn paati opiti Sapphire, awọn ideri lẹnsi foonu alagbeka, Awọn ohun elo amọ, LT, Silicon Carbide SIC, Quartz, ati awọn wafers garawa semikondokito. Pẹlu oye oye ati ohun elo gige-eti, a tayọ ni iṣelọpọ ọja ti kii ṣe deede, ni ero lati jẹ oludari awọn ohun elo optoelectronic ile-iṣẹ giga-imọ-ẹrọ.