Microjet lesa ẹrọ itanna wafer gige SiC ohun elo processing

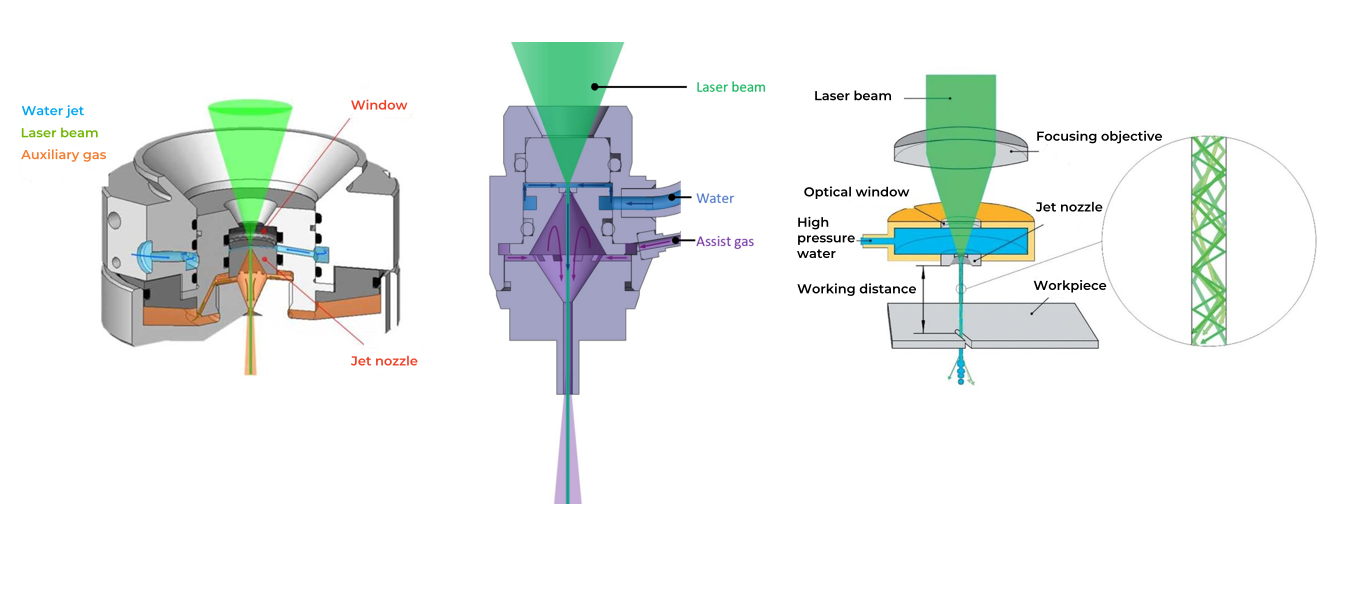

Ilana iṣẹ:

1. Isopọ lesa: laser pulsed (UV / alawọ ewe / infurarẹẹdi) ti wa ni idojukọ inu ọkọ ofurufu omi lati ṣe ikanni gbigbe agbara ti o duro.

2. Itọsọna Liquid: Jet ti o ga julọ (oṣuwọn sisan 50-200m / s) itutu agbegbe ti n ṣatunṣe ati gbigbe awọn idoti kuro lati yago fun ikojọpọ ooru ati idoti.

3. Iyọkuro ohun elo: Agbara laser nfa ipa cavitation ninu omi lati ṣe aṣeyọri processing tutu ti ohun elo (agbegbe ti o kan ooru <1μm).

4. Iṣakoso agbara: atunṣe akoko gidi ti awọn paramita laser (agbara, igbohunsafẹfẹ) ati titẹ jet lati pade awọn iwulo ti awọn ohun elo ati awọn ẹya oriṣiriṣi.

Awọn paramita bọtini:

1. Agbara lesa: 10-500W (atunṣe)

2. Jet opin: 50-300μm

3.Machining yiye: ± 0.5μm (gige), ijinle si iwọn iwọn 10: 1 (liluho)

Awọn anfani imọ-ẹrọ:

(1) Fere odo ooru bibajẹ

- Liquid jet itutu iṣakoso agbegbe ti o kan ooru (HAZ) si ** <1μm **, yago fun awọn dojuijako micro-cracks ti o ṣẹlẹ nipasẹ sisẹ laser aṣa (HAZ jẹ igbagbogbo> 10μm).

(2) Ultra-ga konge machining

- Ige / liluho deede to ** ± 0.5μm ***, eti roughness Ra <0.2μm, din awọn nilo fun ọwọ polishing.

- Ṣe atilẹyin iṣẹ ṣiṣe eto 3D eka (gẹgẹbi awọn iho conical, awọn iho apẹrẹ).

(3) Ibamu ohun elo jakejado

- Awọn ohun elo lile ati brittle: SiC, safire, gilasi, awọn ohun elo amọ (awọn ọna aṣa jẹ rọrun lati fọ).

- Awọn ohun elo ifarabalẹ ooru: awọn polima, awọn sẹẹli ti ibi (ko si eewu ti denaturation gbona).

(4) Idaabobo ayika ati ṣiṣe

- Ko si idoti eruku, omi le ṣe atunlo ati filtered.

- 30% -50% alekun ni iyara sisẹ (la machining).

(5) Iṣakoso oye

- Iṣọkan wiwo ipo ati iṣapeye paramita AI, sisanra ohun elo adaṣe ati awọn abawọn.

Awọn pato imọ-ẹrọ:

| Countertop iwọn didun | 300*300*150 | 400*400*200 |

| Iwọn ila ila XY | Motor laini. Motor laini | Motor laini. Motor laini |

| Iwọn ila ila Z | 150 | 200 |

| Ipo deede μm | +/-5 | +/-5 |

| Titun ipo deede μm | +/-2 | +/-2 |

| Isare G | 1 | 0.29 |

| Iṣakoso nọmba | 3 apa / 3+1 apa / 3+2 apa | 3 apa / 3+1 apa / 3+2 apa |

| Nọmba iṣakoso iru | DPSS Nd: YAG | DPSS Nd: YAG |

| Ìgùn nm | 532/1064 | 532/1064 |

| Ti o ni agbara W | 50/100/200 | 50/100/200 |

| Omi oko ofurufu | 40-100 | 40-100 |

| Ọpa titẹ nozzle | 50-100 | 50-600 |

| Awọn iwọn (ọpa ẹrọ) (iwọn * ipari * iga) mm | 1445*1944*2260 | 1700*1500*2120 |

| Ìwọ̀n (ọ́fíìsì ìdarí) (W * L * H) | 700*2500*1600 | 700*2500*1600 |

| Iwọn (ohun elo) T | 2.5 | 3 |

| àdánù (iṣakoso minisita) KG | 800 | 800 |

| Agbara ṣiṣe | Dada roughness Ra≤1.6um Iyara ṣiṣi ≥1.25mm/s Yiyi gige ≥6mm/s Iyara gige laini ≥50mm/s | Dada roughness Ra≤1.2um Iyara ṣiṣi ≥1.25mm/s Yiyi gige ≥6mm/s Iyara gige laini ≥50mm/s |

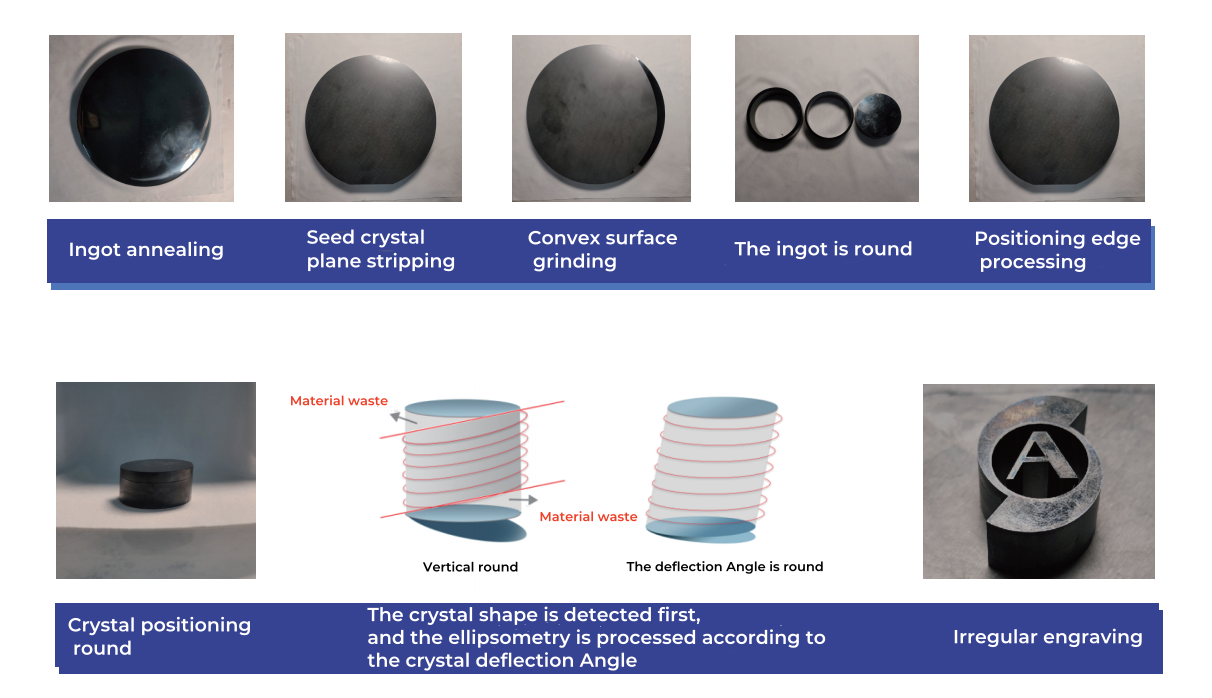

| Fun gallium nitride gara, olekenka-jakejado band aafo semikondokito ohun elo (diamond/Gallium oxide), Aerospace pataki ohun elo, LTCC erogba seramiki sobusitireti, photovoltaic, scintillator gara ati awọn ohun elo miiran processing. Akiyesi: Agbara sisẹ yatọ da lori awọn abuda ohun elo

| ||

Ọran ilana:

Awọn iṣẹ XKH:

XKH pese kan ni kikun ibiti o ti ni kikun aye ọmọ iṣẹ support fun microjet lesa ẹrọ itanna, lati awọn tete ilana idagbasoke ati ẹrọ yiyan ijumọsọrọ, si awọn aarin-oro ti adani eto Integration (pẹlu awọn pataki ibamu ti lesa orisun, ofurufu eto ati adaṣiṣẹ module), si awọn nigbamii isẹ ati ikẹkọ ikẹkọ ati lemọlemọfún ilana ti o dara ju, gbogbo ilana ti wa ni ipese pẹlu ọjọgbọn imọ support egbe; Da lori awọn ọdun 20 ti iriri ẹrọ ṣiṣe deede, a le pese awọn solusan iduro-ọkan pẹlu ijẹrisi ohun elo, iṣafihan iṣelọpọ pupọ ati idahun iyara lẹhin-tita (awọn wakati 24 ti atilẹyin imọ-ẹrọ + ifipamọ awọn ohun elo bọtini) fun awọn ile-iṣẹ oriṣiriṣi bii semikondokito ati iṣoogun, ati ṣe ileri awọn oṣu 12 atilẹyin gigun ati itọju igbesi aye ati iṣẹ igbesoke. Rii daju pe ohun elo alabara nigbagbogbo n ṣetọju iṣẹ ṣiṣe iṣakoso ile-iṣẹ ati iduroṣinṣin.

Alaye aworan atọka