Atẹ seramiki SiC fun Olutọju Wafer pẹlu Atako otutu-giga

Silicon Carbide Seramiki Atẹ (SiC Tray)

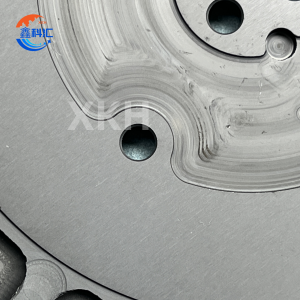

Apakan seramiki ti o ga julọ ti o da lori ohun elo silikoni carbide (SiC), ti a ṣe adaṣe fun awọn ohun elo ile-iṣẹ ilọsiwaju bii iṣelọpọ semikondokito ati iṣelọpọ LED. Awọn iṣẹ pataki rẹ pẹlu ṣiṣe bi gbigbe wafer, pẹpẹ ilana etching, tabi atilẹyin ilana iwọn otutu giga, jijẹ ifarapa igbona ti o yatọ, resistance iwọn otutu giga, ati iduroṣinṣin kemikali lati rii daju isokan ilana ati ikore ọja.

Awọn ẹya ara ẹrọ bọtini

1. Gbona Performance

- Imudara Ooru Giga: 140-300 W/m·K, pataki ju graphite ibile lọ (85 W/m·K), ti o mu ki itu ooru yiyara ati dinku wahala igbona.

- Imugboroosi Gbona Kekere: 4.0×10⁻⁶/℃ (25–1000℃), ohun alumọni ibaramu pẹkipẹki (2.6×10⁻⁶/℃), dindinku awọn ewu abuku gbona.

2. Mechanical Properties

- Agbara giga: Agbara Flexural ≥320 MPa (20℃), sooro si funmorawon ati ipa.

- Lile giga: Mohs líle 9.5, keji nikan si diamond, ti o funni ni resistance yiya ti o ga julọ.

3. Iduroṣinṣin Kemikali

- Resistance Ipata: Sooro si awọn acids ti o lagbara (fun apẹẹrẹ, HF, H₂SO₄), o dara fun awọn agbegbe ilana etching.

- Ti kii ṣe oofa: Ailagbara oofa ti inu <1×10⁻⁶ emu/g, yago fun kikọlu pẹlu awọn ohun elo pipe.

4. Ifarada Ayika Gidigidi

- Igbara otutu-giga: otutu iṣiṣẹ igba pipẹ to 1600-1900 ℃; resistance igba kukuru to 2200 ℃ (ayika ti ko ni atẹgun).

- Resistance Shock Gbona: Koju awọn iyipada iwọn otutu lojiji (ΔT> 1000 ℃) laisi fifọ.

Awọn ohun elo

| Aaye ohun elo | Awọn oju iṣẹlẹ pato | Iye imọ-ẹrọ |

| Iṣẹ iṣelọpọ Semiconductor | Wafer etching (ICP), tinrin-fiimu iwadi oro (MOCVD), CMP polishing | Imudara igbona giga ṣe idaniloju awọn aaye iwọn otutu aṣọ; Imugboroosi igbona kekere dinku oju-iwe wafer. |

| Awọn iṣelọpọ LED | Idagba epitaxial (fun apẹẹrẹ, GaN), dicing wafer, iṣakojọpọ | Dinku awọn abawọn iru-pupọ, imudara iṣẹ ṣiṣe itanna LED ati igbesi aye. |

| Ile-iṣẹ fọtovoltaic | Silicon wafer sintering ileru, PECVD ẹrọ atilẹyin | Iwọn otutu-giga ati resistance mọnamọna gbona fa igbesi aye ohun elo fa. |

| Lesa & Optics | Awọn sobusitireti itutu lesa agbara-giga, awọn atilẹyin eto opiti | Imudara igbona ti o ga julọ jẹ ki itọ ooru iyara ni iyara, diduro awọn paati opiti. |

| Awọn irinṣẹ Analitikali | TGA/DSC ayẹwo holders | Agbara gbigbo kekere ati esi igbona iyara mu ilọsiwaju wiwọn pọ si. |

Awọn anfani Ọja

- Iṣe Apejuwe: Imudara igbona, agbara, ati resistance ipata ti o kọja alumina ati awọn ohun elo amọ nitride silikoni, pade awọn ibeere iṣẹ ṣiṣe to gaju.

- Apẹrẹ iwuwo fẹẹrẹ: iwuwo ti 3.1-3.2 g/cm³ (40% ti irin), idinku fifuye inertial ati imudara deedee išipopada.

- Igbesi aye gigun & Igbẹkẹle: Igbesi aye iṣẹ kọja ọdun 5 ni 1600 ℃, idinku idinku ati idinku awọn idiyele iṣẹ ṣiṣe nipasẹ 30%.

- Isọdi-ara: Ṣe atilẹyin awọn geometries ti o nipọn (fun apẹẹrẹ, awọn ife mimu ti o ni lainidi, awọn atẹ olopopona) pẹlu aṣiṣe alapin <15 μm fun awọn ohun elo pipe.

Awọn pato imọ-ẹrọ

| Ẹka paramita | Atọka |

| Awọn ohun-ini ti ara | |

| iwuwo | ≥3.10 g/cm³ |

| Agbara Flexural (20℃) | 320-410 MPa |

| Imudara Ooru (20℃) | 140–300 W/(m·K) |

| Olùsọdipúpọ̀ Gbona (25–1000℃) | 4.0×10⁻⁶/℃ |

| Awọn ohun-ini Kemikali | |

| Resistance Acid (HF/H₂SO₄) | Ko si ipata lẹhin immersion 24h |

| Ṣiṣe deedee ẹrọ | |

| Fifẹ | ≤15 μm (300×300 mm) |

| Irira Ilẹ (Ra) | ≤0.4 μm |

Awọn iṣẹ XKH

XKH n pese awọn solusan ile-iṣẹ okeerẹ ni idagbasoke aṣa, ẹrọ titọ, ati iṣakoso didara to muna. Fun idagbasoke aṣa, o funni ni mimọ-giga (> 99.999%) ati la kọja (30 – 50% porosity) awọn solusan ohun elo, so pọ pẹlu awoṣe 3D ati kikopa lati mu awọn geometries eka sii fun awọn ohun elo bii semikondokito ati aerospace. Ṣiṣe deede ti o tẹle ilana ṣiṣan: sisẹ lulú → isostatic / titẹ gbigbẹ → 2200 ° C sintering → CNC / diamond lilọ → ayewo, aridaju didan ipele nanometer ati ± 0.01 mm ifarada iwọn. Iṣakoso didara pẹlu idanwo ilana-kikun (akopọ XRD, microstructure SEM, fifẹ 3-point) ati atilẹyin imọ-ẹrọ (iṣapeye ilana, ijumọsọrọ 24/7, ifijiṣẹ ayẹwo wakati 48), jiṣẹ igbẹkẹle, awọn paati iṣẹ ṣiṣe giga fun awọn iwulo ile-iṣẹ ilọsiwaju.

Awọn Ibeere Nigbagbogbo (FAQ)

1. Q: Awọn ile-iṣẹ wo lo nlo awọn atẹrin seramiki carbide silikoni?

A: Ti a lo jakejado ni iṣelọpọ semikondokito (mimu wafer), agbara oorun (awọn ilana PECVD), ohun elo iṣoogun (awọn paati MRI), ati aerospace (awọn ẹya iwọn otutu giga) nitori resistance ooru to gaju ati iduroṣinṣin kemikali.

2. Q: Bawo ni ohun alumọni carbide ṣe jade ni quartz / awọn atẹ gilasi?

A: Idaabobo ijaya ti o ga julọ (to 1800°C vs. quartz's 1100°C), kikọlu oofa odo, ati igbesi aye gigun (ọdun 5+ vs. quartz's 6-12 months).

3. Q: Njẹ awọn atẹrin carbide siliki mu awọn agbegbe ekikan?

A: Bẹẹni. Sooro si HF, H2SO4, ati NaOH, pẹlu <0.01mm ipata/odun, ṣiṣe wọn apẹrẹ fun kemikali etching ati wafer ninu.

4. Q: Ṣe awọn atẹrin carbide silikoni ni ibamu pẹlu adaṣe?

A: Bẹẹni. Ti a ṣe apẹrẹ fun gbigba igbale ati mimu roboti, pẹlu fifẹ dada <0.01mm lati yago fun idoti patiku ni awọn aṣọ adaṣe adaṣe.

5. Q: Kini afiwe iye owo la awọn ohun elo ibile?

A: Iye owo iwaju ti o ga julọ (kuotisi 3-5x) ṣugbọn 30-50% kekere TCO nitori igbesi aye gigun, akoko idinku, ati awọn ifowopamọ agbara lati imudara igbona giga.