Eto Iṣalaye Wafer fun Iwọn Iṣalaye Crystal

Ifihan ohun elo

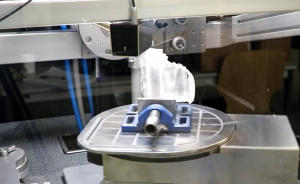

Awọn ohun elo iṣalaye Wafer jẹ awọn ẹrọ titọ ti o da lori awọn ipilẹ X-ray diffraction (XRD), ti a lo ni akọkọ ni iṣelọpọ semikondokito, awọn ohun elo opiti, awọn ohun elo amọ, ati awọn ile-iṣẹ ohun elo kirisita miiran.

Awọn ohun elo wọnyi pinnu iṣalaye latissi gara ati itọsọna gige kongẹ tabi awọn ilana didan. Awọn ẹya pataki pẹlu:

- Awọn wiwọn pipe-giga:Agbara lati yanju awọn ọkọ ofurufu crystallographic pẹlu awọn ipinnu angula si isalẹ 0.001°.

- Ibamu apẹẹrẹ nla:Ṣe atilẹyin awọn wafers to 450 mm ni iwọn ila opin ati awọn iwuwo ti 30 kg, o dara fun awọn ohun elo bii silikoni carbide (SiC), safire, ati silikoni (Si).

- Apẹrẹ modulu:Awọn iṣẹ ṣiṣe ti o gbooro pẹlu itupale iṣagbega gbigbọn, aworan afọwọṣe oju dada 3D, ati awọn ẹrọ iṣakojọpọ fun sisẹ apẹẹrẹ-ọpọlọpọ.

Awọn paramita Imọ-ẹrọ bọtini

| Ẹka paramita | Aṣoju Awọn iye / Iṣeto ni |

| Orisun X-ray | Cu-Kα (0.4×1 mm ibi idojukọ), 30 kV foliteji isare, 0-5 mA tube adijositabulu lọwọlọwọ |

| Ibiti angula | θ: -10° si +50°; 2θ: -10° si +100° |

| Yiye | Ipinnu igun titẹ: 0.001°, wiwa abawọn dada: ± 30 arcseconds (igi gbigbọn) |

| Iyara Ṣiṣayẹwo | Ayẹwo Omega pari iṣalaye lattice ni kikun ni iṣẹju-aaya 5; Ayẹwo Theta gba ~ iṣẹju 1 |

| Ipele Ayẹwo | V-groove, afamora pneumatic, yiyi igun-ọpọlọpọ, ibaramu pẹlu awọn wafers 2–8-inch |

| Awọn iṣẹ Imugboroosi | Itupalẹ ohun ti o tẹ apata, aworan aworan 3D, ẹrọ akopọ, iṣawari abawọn opitika (awọn cratches, GBs) |

Ilana Ṣiṣẹ

1. X-ray Diffraction Foundation

- Awọn ina-X-ray ṣe ajọṣepọ pẹlu awọn atomiki atomiki ati awọn elekitironi ninu lattice gara, ti n ṣe agbekalẹ awọn ilana isọdi. Ofin Bragg (nλ = 2d sinθ) n ṣe akoso ibatan laarin awọn igun iyapa (θ) ati aaye lattice (d).

Awọn aṣawari gba awọn ilana wọnyi, eyiti a ṣe atupale lati ṣe atunto igbekalẹ crystallographic.

2. Imọ-ẹrọ Ṣiṣayẹwo Omega

- Awọn gara n yi continuously ni ayika kan ti o wa titi ipo nigba ti X-egungun itanna o.

- Awọn oniwadi gba awọn ifihan agbara diffraction kọja ọpọlọpọ awọn ọkọ ofurufu crystallographic, ṣiṣe ipinnu iṣalaye lattice ni kikun ni iṣẹju-aaya 5.

3. Iṣayẹwo Curve Rocking

- Igun kirisita ti o wa titi pẹlu oriṣiriṣi awọn igun iṣẹlẹ iṣẹlẹ X-ray lati wiwọn iwọn tente oke (FWHM), ṣiṣe ayẹwo awọn abawọn lattice ati igara.

4. Iṣakoso aifọwọyi

- PLC ati awọn atọkun iboju ifọwọkan jẹ ki awọn igun gige tito tito tẹlẹ, esi akoko gidi, ati isọpọ pẹlu awọn ẹrọ gige fun iṣakoso titiipa-pipade.

Awọn anfani ati Awọn ẹya ara ẹrọ

1. konge ati ṣiṣe

- Ipese igun ± 0.001°, ipinnu wiwa abawọn <30 awọn iṣẹju aaya.

- Iyara ọlọjẹ Omega jẹ 200× yiyara ju awọn iwoye Theta ibile.

2. Modularity ati Scalability

- Expandable fun awọn ohun elo amọja (fun apẹẹrẹ, SiC wafers, awọn abẹfẹlẹ tobaini).

- Ṣepọ pẹlu awọn eto MES fun ibojuwo iṣelọpọ akoko gidi.

3. Ibamu ati Iduroṣinṣin

- Ngba awọn ayẹwo ni irisi alaibamu (fun apẹẹrẹ, awọn ingots oniyebiye sisan).

- Apẹrẹ-tutu afẹfẹ dinku awọn iwulo itọju.

4. Iṣẹ ti oye

- Isọdi-ọkan-ọkan ati sisẹ iṣẹ-ṣiṣe pupọ.

- Isọdi-laifọwọyi pẹlu awọn kirisita itọkasi lati dinku aṣiṣe eniyan.

Awọn ohun elo

1. Iṣẹ iṣelọpọ Semikondokito

- Iṣalaye dicing Wafer: Ṣe ipinnu Si, SiC, awọn iṣalaye wafer GaN fun ṣiṣe gige iṣapeye.

- Àbùkù ìyàwòrán: Ṣe idanimọ awọn idọti oju-ilẹ tabi awọn iṣipopada lati ṣe ilọsiwaju ikore-pipẹ.

2. Awọn ohun elo opitika

- Awọn kirisita ti kii ṣe lainidi (fun apẹẹrẹ, LBO, BBO) fun awọn ẹrọ lesa.

- Itọkasi itọka wafer oniyebiye fun awọn sobusitireti LED.

3. Awọn ohun elo seramiki ati awọn akojọpọ

- Ṣe itupalẹ iṣalaye ọkà ni Si3N4 ati ZrO2 fun awọn ohun elo iwọn otutu giga.

4. Iwadi ati Iṣakoso Didara

- Awọn ile-ẹkọ giga / awọn ile-iṣẹ fun idagbasoke ohun elo aramada (fun apẹẹrẹ, awọn alloy entropy giga).

- QC ile-iṣẹ lati rii daju pe aitasera ipele.

Awọn iṣẹ XKH

XKH n funni ni atilẹyin imọ-ẹrọ igbesi aye okeerẹ fun awọn ohun elo iṣalaye wafer, pẹlu fifi sori ẹrọ, iṣapeye paramita ilana, itupalẹ igbi gbigbọn, ati iyaworan abawọn oju ilẹ 3D. Awọn ojutu ti a ṣe deede (fun apẹẹrẹ, imọ-ẹrọ stacking ingot) ti pese lati jẹki semikondokito ati ṣiṣe iṣelọpọ ohun elo opiti nipasẹ ju 30%. Ẹgbẹ kan ti o ṣe iyasọtọ n ṣe ikẹkọ lori aaye, lakoko ti 24/7 atilẹyin latọna jijin ati rirọpo apakan apakan iyara rii daju igbẹkẹle ohun elo.