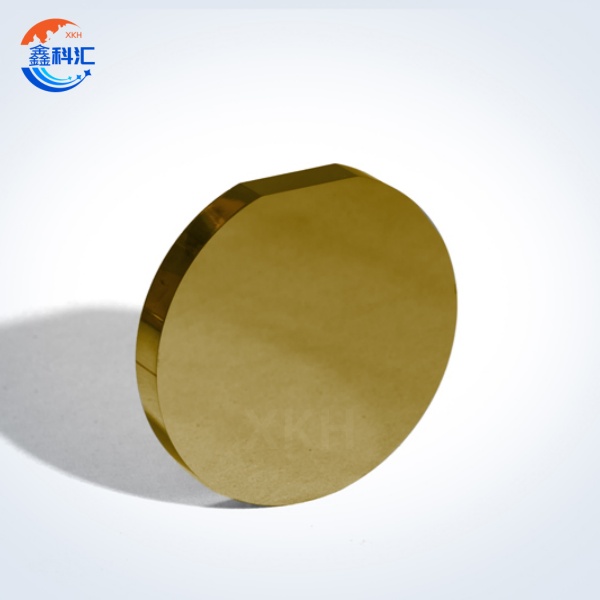

12 inch SiC sobusitireti Diamita 300mm Sisanra 750μm 4H-N Iru le jẹ adani

Imọ paramita

| 12 inch Silicon Carbide (SiC) sobusitireti pato | |||||

| Ipele | ZeroMPD iṣelọpọ Ite(Ipele Z) | Standard Production Ite(P Ite) | Idiwon ite (Ite D) | ||

| Iwọn opin | 3 00 mm ~ 1305mm | ||||

| Sisanra | 4H-N | 750μm± 15 μm | 750μm± 25 μm | ||

| 4H-SI | 750μm± 15 μm | 750μm± 25 μm | |||

| Wafer Iṣalaye | Pa axis: 4.0° si <1120>±0.5° fun 4H-N, Lori ipo: <0001>±0.5° fun 4H-SI | ||||

| Iwuwo Micropipe | 4H-N | ≤0.4cm-2 | ≤4cm-2 | ≤25cm-2 | |

| 4H-SI | ≤5cm-2 | ≤10cm-2 | ≤25cm-2 | ||

| Resistivity | 4H-N | 0.015 ~ 0.024 Ω · cm | 0.015 ~ 0.028 Ω · cm | ||

| 4H-SI | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |||

| Primary Flat Iṣalaye | {10-10} ±5.0° | ||||

| Primary Flat Gigun | 4H-N | N/A | |||

| 4H-SI | Ogbontarigi | ||||

| Iyasoto eti | 3 mm | ||||

| LTV/TTV/ Teriba / Warp | ≤5μm/≤15μm/≤35 μm/≤55 μm | ≤5μm/≤15μm/≤35 □ μm/≤55 □ μm | |||

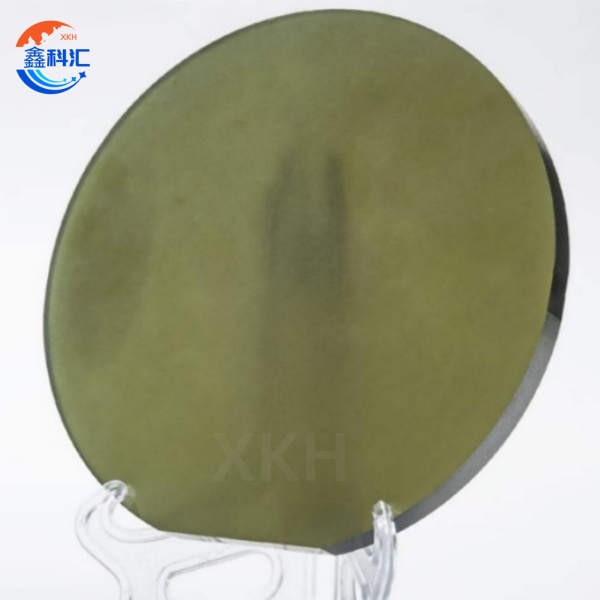

| Irora | Polish Ra≤1 nm | ||||

| CMP Ra≤0.2 nm | Ra≤0.5 nm | ||||

| Eti dojuijako Nipa Ga kikankikan Light Hex farahan Nipa High kikankikan Light Awọn agbegbe Polytype Nipa Imọlẹ Kikan Giga Visual Erogba Ifisi Silicon Surface Scratches Nipa Giga kikankikan Light | Ko si Agbegbe akojọpọ ≤0.05% Ko si Agbegbe akojọpọ ≤0.05% Ko si | Akopọ ipari ≤ 20 mm, ipari kan≤2 mm Agbegbe akojọpọ ≤0.1% Agbegbe akojọpọ≤3% Agbegbe akojọpọ ≤3% Àkópọ̀ gígùn≤1×ìwọ̀n òpin wafer | |||

| Awọn eerun eti Nipa Imọlẹ Imọlẹ giga | Ko si idasilẹ ≥0.2mm fifẹ ati ijinle | 7 laaye, ≤1 mm kọọkan | |||

| (TSD) Threading dabaru dislocation | ≤500 cm-2 | N/A | |||

| (BPD) Ipilẹ ofurufu dislocation | ≤1000 cm-2 | N/A | |||

| Ohun alumọni dada kontaminesonu Nipa High kikankikan Light | Ko si | ||||

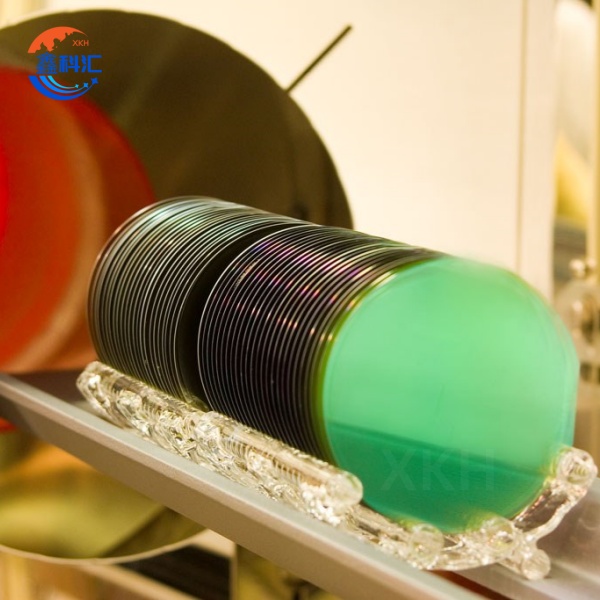

| Iṣakojọpọ | Kasẹti-wafer pupọ Tabi Apoti Wafer Nikan | ||||

| Awọn akọsilẹ: | |||||

| 1 Awọn opin awọn abawọn lo si gbogbo oju wafer ayafi fun agbegbe iyasoto eti. 2Awọn idọti yẹ ki o ṣayẹwo lori oju Si nikan. 3 Awọn data dislocation jẹ nikan lati KOH etched wafers. | |||||

Key Awọn ẹya ara ẹrọ

1.Production Agbara ati Awọn anfani Iye owo: Iṣelọpọ pupọ ti 12-inch SiC substrate (12-inch silicon carbide substrate) jẹ ami akoko tuntun ni iṣelọpọ semikondokito. Nọmba awọn eerun ti o gba lati wafer ẹyọkan de awọn akoko 2.25 ti awọn sobusitireti 8-inch, wiwakọ fifo taara ni ṣiṣe iṣelọpọ. Awọn esi alabara tọkasi pe gbigba awọn sobusitireti 12-inch ti dinku awọn idiyele iṣelọpọ module agbara wọn nipasẹ 28%, ṣiṣẹda anfani ifigagbaga ipinnu ni ọja ti njijadu lile.

2.Outstanding Physical Properties: Awọn 12-inch SiC sobusitireti jogun gbogbo awọn anfani ti silikoni carbide ohun elo - awọn oniwe-gbona elekitiriki ni 3 igba ti ohun alumọni, nigba ti awọn oniwe- didenukole aaye agbara Gigun 10 igba ti ohun alumọni. Awọn abuda wọnyi jẹ ki awọn ẹrọ ti o da lori awọn sobusitireti 12-inch ṣiṣẹ ni iduroṣinṣin ni awọn agbegbe iwọn otutu ti o ga ju 200 ° C, ṣiṣe wọn ni pataki ni pataki fun awọn ohun elo ibeere gẹgẹbi awọn ọkọ ina.

3.Surface Treatment Technology: A ti ṣe agbekalẹ ilana polishing kemikali aramada kan (CMP) pataki fun 12-inch SiC sobsitireti, iyọrisi ipele ipele atomiki (Ra <0.15nm). Aṣeyọri yii yanju ipenija agbaye ti itọju dada ohun alumọni carbide wafer iwọn ila opin nla, imukuro awọn idiwọ fun idagbasoke epitaxial didara ga.

4.Thermal Management Performance: Ni awọn ohun elo ti o wulo, 12-inch SiC substrates ṣe afihan awọn agbara ifasilẹ ooru ti o ṣe pataki. Awọn data idanwo fihan pe labẹ iwuwo agbara kanna, awọn ẹrọ ti o nlo awọn sobusitireti 12-inch ṣiṣẹ ni awọn iwọn otutu 40-50 ° C ni isalẹ ju awọn ohun elo ti o da lori ohun alumọni, ti o fa igbesi aye iṣẹ ohun elo ni pataki.

Awọn ohun elo akọkọ

1.New Energy Vehicle Ecosystem: Awọn 12-inch SiC sobusitireti (12-inch silikoni carbide sobsitireti) ti wa ni revolutionizing ina ti nše ọkọ powertrain faaji. Lati awọn ṣaja inu (OBC) si awọn oluyipada awakọ akọkọ ati awọn eto iṣakoso batiri, awọn ilọsiwaju ṣiṣe ti o mu nipasẹ awọn sobusitireti 12-inch pọ si ibiti ọkọ ayọkẹlẹ nipasẹ 5-8%. Awọn ijabọ lati ọdọ oluṣe adaṣe oludari kan tọka pe gbigba awọn sobusitireti inch 12 wa dinku pipadanu agbara ninu eto gbigba agbara iyara wọn nipasẹ iwunilori 62%.

2.Aṣatunṣe Agbara Atunṣe: Ni awọn ibudo agbara fọtovoltaic, awọn inverters ti o da lori awọn sobusitireti SiC 12-inch kii ṣe ẹya awọn ifosiwewe fọọmu kekere nikan ṣugbọn tun ṣe aṣeyọri ṣiṣe iyipada ti o kọja 99%. Paapa ni awọn oju iṣẹlẹ iran pinpin, ṣiṣe giga yii tumọ si awọn ifowopamọ ọdọọdun ti awọn ọgọọgọrun egbegberun yuan ni awọn adanu ina fun awọn oniṣẹ.

3.Industrial Automation: Awọn oluyipada igbohunsafẹfẹ ti nlo awọn ohun elo 12-inch ṣe afihan iṣẹ ti o dara julọ ni awọn roboti ile-iṣẹ, awọn irinṣẹ ẹrọ CNC, ati awọn ohun elo miiran. Awọn abuda iyipada-igbohunsafẹfẹ giga wọn mu iyara idahun mọto pọ si nipasẹ 30% lakoko ti o dinku kikọlu itanna si idamẹta ti awọn solusan aṣa.

4.Consumer Electronics Innovation: Next-iran foonuiyara sare-gbigba agbara imo ero ti bere si gbigba 12-inch SiC sobsitireti. O jẹ iṣẹ akanṣe pe awọn ọja gbigba agbara ni iyara loke 65W yoo yipada ni kikun si awọn ipinnu ohun alumọni ohun alumọni, pẹlu awọn sobusitireti 12-inch ti n yọ jade bi yiyan iṣẹ ṣiṣe idiyele to dara julọ.

Awọn iṣẹ adani XKH fun 12-inch SiC Substrate

Lati pade awọn ibeere kan pato fun awọn sobusitireti SiC-inch 12 (awọn sobusitireti ohun alumọni silikoni 12-inch), XKH nfunni ni atilẹyin iṣẹ okeerẹ:

1.Sisanra isọdi:

A pese awọn sobusitireti 12-inch ni ọpọlọpọ awọn pato sisanra pẹlu 725μm lati pade awọn iwulo ohun elo oriṣiriṣi.

2.Doping fojusi:

Iṣẹ iṣelọpọ wa ṣe atilẹyin awọn iru iṣe adaṣe lọpọlọpọ pẹlu iru n-iru ati awọn sobusitireti iru p, pẹlu iṣakoso resistivity kongẹ ni iwọn 0.01-0.02Ω · cm.

3.Awọn iṣẹ idanwo:

Pẹlu ohun elo idanwo ipele wafer pipe, a pese awọn ijabọ ayewo ni kikun.

XKH loye pe alabara kọọkan ni awọn ibeere alailẹgbẹ fun awọn sobusitireti SiC 12-inch. Nitorinaa a nfunni awọn awoṣe ifowosowopo iṣowo rọ lati pese awọn solusan ifigagbaga julọ, boya fun:

· R&D awọn ayẹwo

Awọn rira iṣelọpọ iwọn didun

Awọn iṣẹ adani wa rii daju pe a le pade imọ-ẹrọ kan pato ati awọn iwulo iṣelọpọ fun awọn sobusitireti SiC-inch 12.