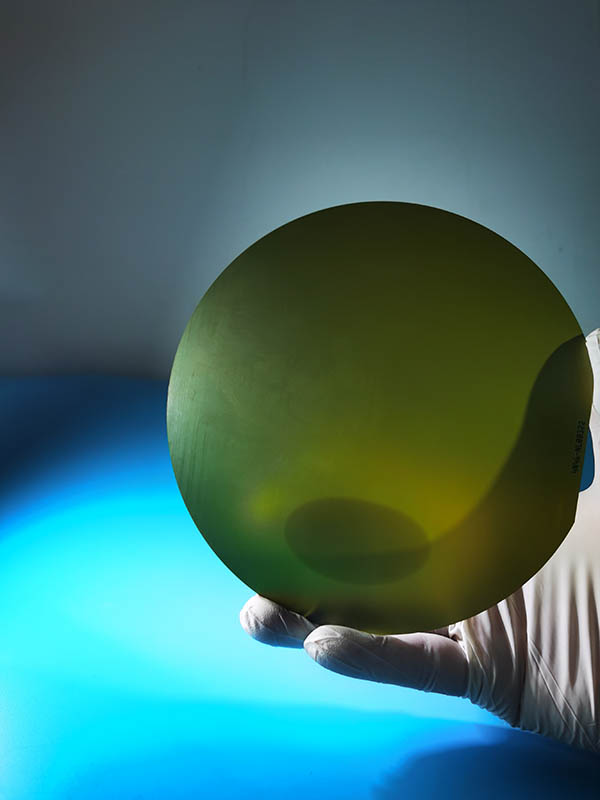

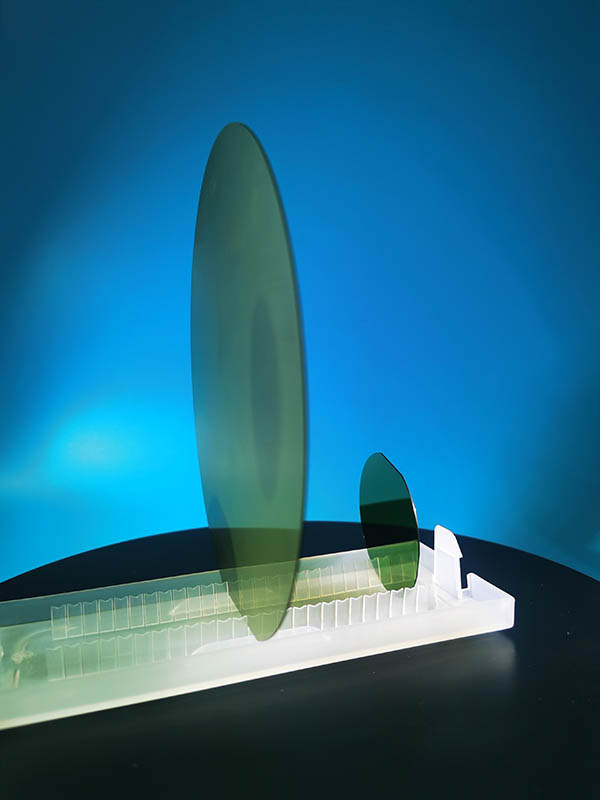

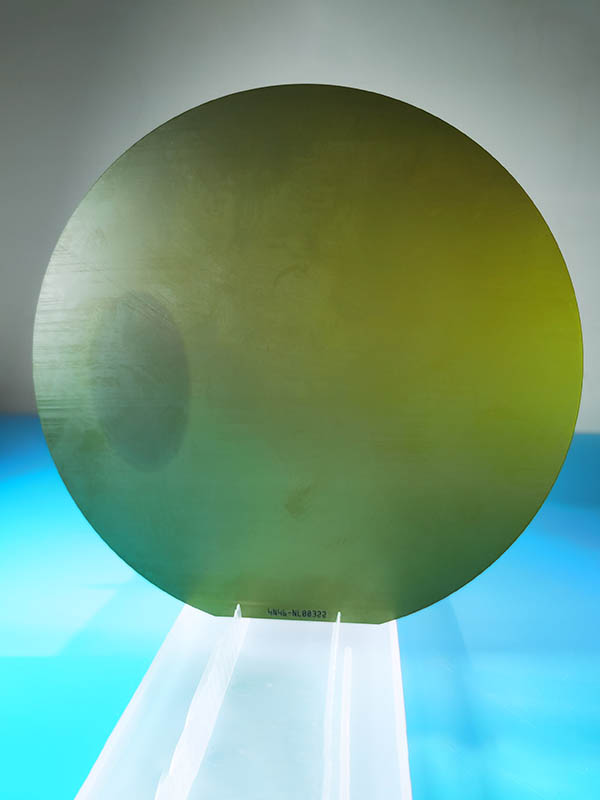

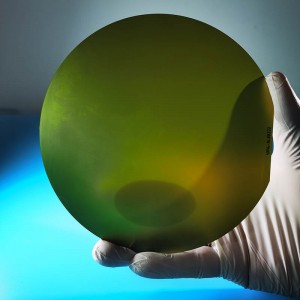

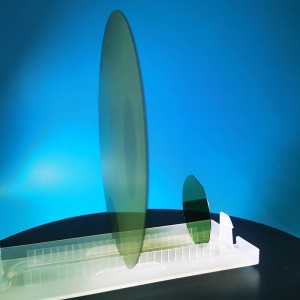

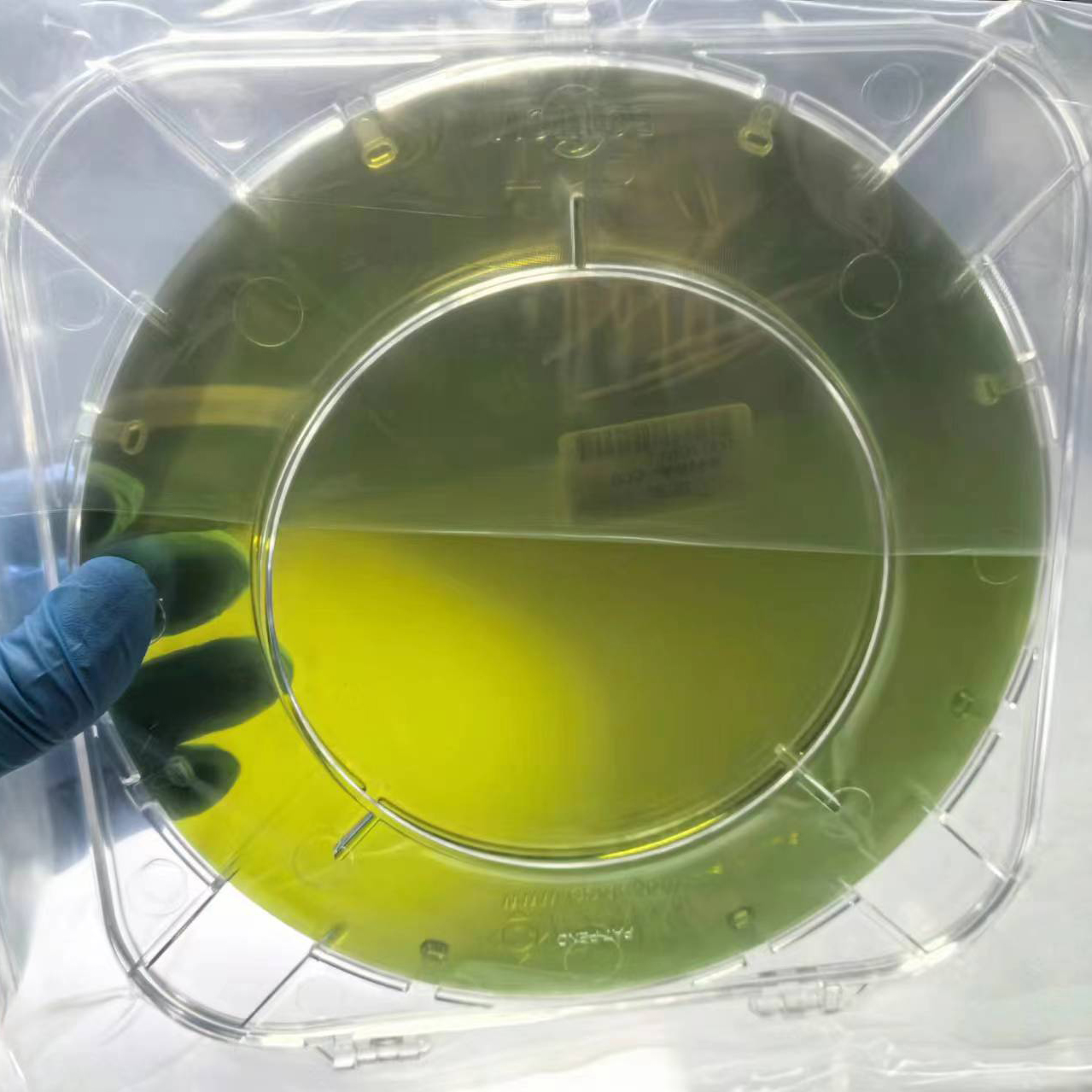

8Inch 200mm 4H-N SiC Wafer Conductive idinwon iwadi ite

Nitori awọn ohun-ini alailẹgbẹ ti ara ati itanna, 200mm SiC wafer semikondokito ohun elo ni a lo lati ṣẹda iṣẹ-giga, iwọn otutu giga, sooro-itanna, ati awọn ẹrọ itanna igbohunsafẹfẹ giga. Iye owo sobusitireti 8inch SiC n dinku diẹ sii bi imọ-ẹrọ ti ni ilọsiwaju diẹ sii ati ibeere naa dagba. Awọn idagbasoke imọ-ẹrọ aipẹ yori si iṣelọpọ iwọn iṣelọpọ ti awọn wafers 200mm SiC. Awọn anfani akọkọ ti awọn ohun elo semikondokito SiC wafer ni lafiwe pẹlu Si ati GaAs wafers: Agbara aaye ina ti 4H-SiC lakoko didenukole ọsan jẹ diẹ sii ju aṣẹ titobi ti o ga ju awọn iye ti o baamu fun Si ati GaAs. Eleyi nyorisi kan significant idinku ninu awọn on-ipinle resistivity Ron. Irẹwẹsi-kekere lori ipinlẹ, ni idapo pẹlu iwuwo lọwọlọwọ giga ati adaṣe igbona, ngbanilaaye lilo iku kekere pupọ fun awọn ẹrọ agbara. Awọn ga gbona elekitiriki ti SiC din awọn gbona resistance ti awọn ërún. Awọn ohun-ini itanna ti awọn ẹrọ ti o da lori awọn wafers SiC jẹ iduroṣinṣin pupọ ni akoko ati lori iduroṣinṣin iwọn otutu, eyiti o ṣe idaniloju igbẹkẹle giga ti awọn ọja. Ohun alumọni carbide jẹ lalailopinpin sooro si lile Ìtọjú, eyi ti ko ni degrade awọn itanna-ini ti awọn ërún. Iwọn otutu iṣiṣẹ diwọn giga ti gara (diẹ ẹ sii ju 6000C) gba ọ laaye lati ṣẹda awọn ẹrọ ti o gbẹkẹle gaan fun awọn ipo iṣẹ lile ati awọn ohun elo pataki. Ni lọwọlọwọ, a le pese ipele kekere 200mmSiC wafers ni imurasilẹ ati nigbagbogbo ati ni ọja diẹ ninu ile-itaja naa.

Sipesifikesonu

| Nọmba | Nkan | Ẹyọ | Ṣiṣejade | Iwadi | Idiwon |

| 1. paramita | |||||

| 1.1 | oniruuru | -- | 4H | 4H | 4H |

| 1.2 | dada iṣalaye | ° | <11-20>4±0.5 | <11-20>4±0.5 | <11-20>4±0.5 |

| 2. Electrical paramita | |||||

| 2.1 | dopant | -- | n-iru Nitrogen | n-iru Nitrogen | n-iru Nitrogen |

| 2.2 | resistivity | ohm · cm | 0.015 ~ 0.025 | 0.01 ~ 0.03 | NA |

| 3. paramita ẹrọ | |||||

| 3.1 | opin | mm | 200± 0.2 | 200± 0.2 | 200± 0.2 |

| 3.2 | sisanra | μm | 500±25 | 500±25 | 500±25 |

| 3.3 | Iṣalaye ogbontarigi | ° | [1-100]±5 | [1-100]±5 | [1-100]±5 |

| 3.4 | Ogbontarigi Ijinle | mm | 1 ~ 1.5 | 1 ~ 1.5 | 1 ~ 1.5 |

| 3.5 | LTV | μm | ≤5(10mm*10mm) | ≤5(10mm*10mm) | ≤10(10mm*10mm) |

| 3.6 | TTV | μm | ≤10 | ≤10 | ≤15 |

| 3.7 | Teriba | μm | -25-25 | -45-45 | -65-65 |

| 3.8 | Ijagun | μm | ≤30 | ≤50 | ≤70 |

| 3.9 | AFM | nm | Ra≤0.2 | Ra≤0.2 | Ra≤0.2 |

| 4. Ilana | |||||

| 4.1 | iwuwo micropipe | ea/cm2 | ≤2 | ≤10 | ≤50 |

| 4.2 | irin akoonu | awọn ọta / cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | TSD | ea/cm2 | ≤500 | ≤1000 | NA |

| 4.4 | BPD | ea/cm2 | ≤2000 | ≤5000 | NA |

| 4.5 | TED | ea/cm2 | ≤7000 | ≤10000 | NA |

| 5. Didara to dara | |||||

| 5.1 | iwaju | -- | Si | Si | Si |

| 5.2 | dada pari | -- | Si-oju CMP | Si-oju CMP | Si-oju CMP |

| 5.3 | patiku | ea/wafer | ≤100(iwọn≥0.3μm) | NA | NA |

| 5.4 | ibere | ea/wafer | ≤5, Lapapọ Gigun≤200mm | NA | NA |

| 5.5 | Eti awọn eerun / indents / dojuijako / abawọn / koto | -- | Ko si | Ko si | NA |

| 5.6 | Awọn agbegbe Polytype | -- | Ko si | Agbegbe ≤10% | Agbegbe ≤30% |

| 5.7 | iwaju siṣamisi | -- | Ko si | Ko si | Ko si |

| 6. Didara pada | |||||

| 6.1 | pada pari | -- | C-oju MP | C-oju MP | C-oju MP |

| 6.2 | ibere | mm | NA | NA | NA |

| 6.3 | Ẹyin abawọn eti eerun / indents | -- | Ko si | Ko si | NA |

| 6.4 | Pada roughness | nm | Ra≤5 | Ra≤5 | Ra≤5 |

| 6.5 | Pada siṣamisi | -- | Ogbontarigi | Ogbontarigi | Ogbontarigi |

| 7. eti | |||||

| 7.1 | eti | -- | Chamfer | Chamfer | Chamfer |

| 8. Package | |||||

| 8.1 | apoti | -- | Epi-setan pẹlu igbale apoti | Epi-setan pẹlu igbale apoti | Epi-setan pẹlu igbale apoti |

| 8.2 | apoti | -- | Olona-wafer apoti kasẹti | Olona-wafer apoti kasẹti | Olona-wafer apoti kasẹti |

Alaye aworan atọka