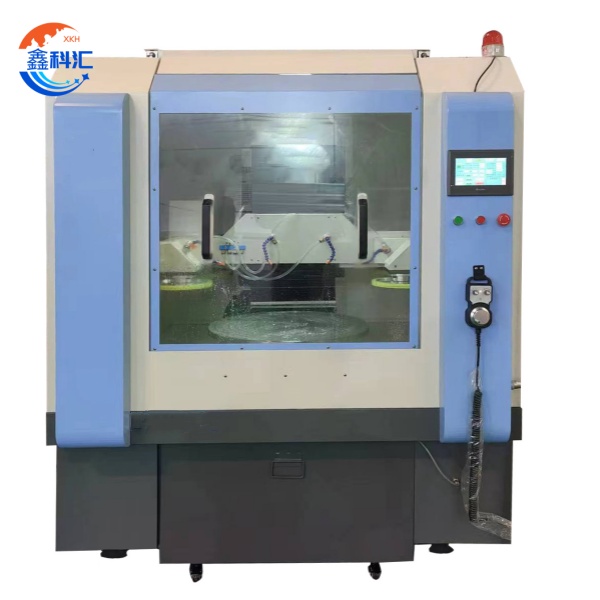

Ohun elo Ige Wafer Aifọwọyi Ni kikun Ige Ige Iwọn 8inch/12inch Wafer

Imọ paramita

| Paramita | Ẹyọ | Sipesifikesonu |

| O pọju Workpiece Iwon | mm | ø12" |

| Spindle | Iṣeto ni | Spindle Nikan |

| Iyara | 3,000-60,000 rpm | |

| Agbara Ijade | 1.8 kW (iyan 2.4) ni 30,000 min⁻¹ | |

| Max Blade Dia. | Ø58 mm | |

| X-Axis | Ige Range | 310 mm |

| Y-apapọ | Ige Range | 310 mm |

| Igbesẹ Ilọsiwaju | 0.0001 mm | |

| Ipo Yiye | ≤0.003 mm/310 mm, ≤0.002 mm/5 mm (aṣiṣe ẹyọkan) | |

| Z-Axis | Ipinnu gbigbe | 0.00005 mm |

| Atunṣe | 0.001 mm | |

| θ-Axis | Iyipo ti o pọju | 380 iwọn |

| Spindle Iru | Spindle ẹyọkan, ni ipese pẹlu abẹfẹlẹ lile fun gige oruka | |

| Oruka-Ige Yiye | μm | ± 50 |

| Wafer Ipo Yiye | μm | ± 50 |

| Nikan-Wafer Ṣiṣe | min / wafer | 8 |

| Olona-Wafer Ṣiṣe | Up to 4 wafers ni ilọsiwaju ni nigbakannaa | |

| Ohun elo iwuwo | kg | ≈3,200 |

| Awọn iwọn Ohun elo (W×D×H) | mm | 2,730 × 1,550 × 2,070 |

Ilana Ilana

Eto naa ṣaṣeyọri iṣẹ gige gige iyasọtọ nipasẹ awọn imọ-ẹrọ pataki wọnyi:

1.Intelligent Motion Iṣakoso System:

Wakọ mọto laini pipe-giga (tun gbe deede: ± 0.5μm)

· Iṣakoso amuṣiṣẹpọ mẹfa-apa ti n ṣe atilẹyin igbero itọpa eka

· Awọn algoridimu titaniji gbigbọn akoko gidi ti n ṣe idaniloju iduroṣinṣin gige

2.To ti ni ilọsiwaju erin System:

* sensọ giga lesa 3D ti a ṣepọ (ipeye: 0.1μm)

· Ipo wiwo CCD ti o ga (megapiksẹli 5)

· Online didara ayewo module

3.Fully aládàáṣiṣẹ ilana:

· Ikojọpọ/gbigbi aifọwọyi (ibaramu ni wiwo boṣewa FOUP)

· Ni oye ayokuro eto

· Ẹka mimọ-pipade (mimọ: Kilasi 10)

Awọn ohun elo Aṣoju

Ohun elo yii n pese iye pataki kọja awọn ohun elo iṣelọpọ semikondokito:

| Aaye Ohun elo | Awọn ohun elo ilana | Awọn anfani Imọ-ẹrọ |

| IC iṣelọpọ | 8/12 "Silicon Wafers | Ṣe ilọsiwaju titete lithography |

| Awọn ẹrọ agbara | SiC/GaN Wafers | Idilọwọ awọn abawọn eti |

| Awọn sensọ MEMS | SOI Wafers | Ṣe idaniloju igbẹkẹle ẹrọ |

| Awọn ẹrọ RF | GaAs Wafers | Ṣe ilọsiwaju iṣẹ-igbohunsafẹfẹ giga |

| Iṣakojọpọ to ti ni ilọsiwaju | Wafers ti a tunṣe | Ṣe alekun ikore apoti |

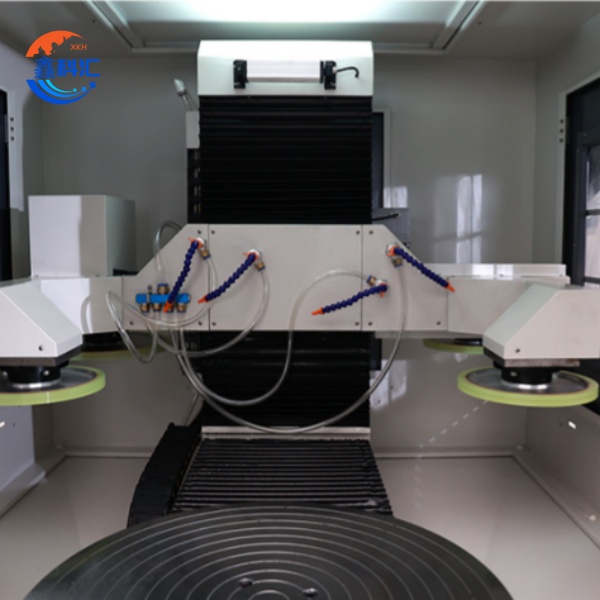

Awọn ẹya ara ẹrọ

1.Four-ibudo iṣeto ni fun ga processing ṣiṣe;

2.Stable TAIKO oruka debonding ati yiyọ;

3.High ibamu pẹlu bọtini consumables;

4.Multi-axis synchronous trimming technology ṣe idaniloju gige eti pipe;

5.Fully aládàáṣiṣẹ ilana sisan significantly din laala owo;

6.Customized worktable oniru kí idurosinsin processing ti pataki ẹya;

Awọn iṣẹ

1.Ring-drop erin eto;

2.Automatic worktable cleaning;

3.Intelligent UV debonding eto;

4.Operation log gbigbasilẹ;

5.Factory automation module integration;

Ifaramo Iṣẹ

XKH n pese okeerẹ, awọn iṣẹ atilẹyin igbesi aye kikun ti a ṣe apẹrẹ lati mu iṣẹ ohun elo pọ si ati ṣiṣe ṣiṣe ni gbogbo irin-ajo iṣelọpọ rẹ.

1. Awọn iṣẹ isọdi

· Iṣeto ni Awọn ohun elo ti a ṣe deede: Ẹgbẹ imọ-ẹrọ wa ṣe ifọwọsowọpọ ni pẹkipẹki pẹlu awọn alabara lati mu awọn eto eto eto (iyara gige gige, yiyan abẹfẹlẹ, bbl) da lori awọn ohun-ini ohun elo kan pato (Si / SiC / GaAs) ati awọn ibeere ilana.

· Atilẹyin Idagbasoke Ilana: A nfunni ni ṣiṣe ayẹwo pẹlu awọn ijabọ itupalẹ alaye pẹlu wiwọn roughness eti ati aworan aworan abawọn.

· Idagbasoke Iṣọkan Awọn ohun elo: Fun awọn ohun elo aramada (fun apẹẹrẹ, Ga₂O₃), a ṣe alabaṣepọ pẹlu awọn aṣelọpọ ti o jẹ asiwaju lati ṣe agbekalẹ ohun elo-pato awọn abẹfẹlẹ / awọn opiti lesa.

2. Professional Technical Support

· Atilẹyin Oju-aaye ti a ṣe iyasọtọ: Fi awọn onimọ-ẹrọ ti a fọwọsi fun awọn ipele rampu to ṣe pataki (paapaa awọn ọsẹ 2-4), ibora:

Isọdiwọn ohun elo & ilana atunṣe to dara

Ikẹkọ oye oniṣẹ

ISO Kilasi 5 itọsọna isọpọ mimọ

· Itọju Asọtẹlẹ: Awọn sọwedowo ilera idamẹrin pẹlu itupalẹ gbigbọn ati awọn iwadii moto servo lati ṣe idiwọ akoko isunmi ti a ko gbero.

· Abojuto latọna jijin: ipasẹ iṣẹ ṣiṣe ohun elo akoko gidi nipasẹ pẹpẹ IoT wa (JCFront Connect®) pẹlu awọn titaniji anomaly adaṣe.

3. Iye-fikun Services

· Ipilẹ Imọ ilana: Wọle si 300+ awọn ilana gige ti a fọwọsi fun ọpọlọpọ awọn ohun elo (imudojuiwọn ni idamẹrin).

· Iṣatunṣe ọna-ọna ọna ẹrọ: ṣe ẹri idoko-owo ni ọjọ iwaju pẹlu awọn ọna iṣagbega hardware/software (fun apẹẹrẹ, module wiwa abawọn orisun AI).

Idahun Pajawiri: Ti ṣe iṣeduro ayẹwo wiwa latọna jijin wakati 4 ati idasi-wakati 48 lori aaye (agbegbe agbaye).

4. Awọn amayederun iṣẹ

· Ẹri Iṣẹ: Ifaramọ adehun si ≥98% akoko ohun elo pẹlu awọn akoko idahun SLA-ti ṣe atilẹyin.

Ilọsiwaju Ilọsiwaju

A ṣe awọn iwadii itelorun alabara lododun ati ṣe awọn ipilẹṣẹ Kaizen lati jẹki ifijiṣẹ iṣẹ. Ẹgbẹ R&D wa tumọ awọn oye aaye sinu awọn iṣagbega ohun elo – 30% ti awọn ilọsiwaju famuwia wa lati awọn esi alabara.