Ga-konge lesa Micromachining System

Key Awọn ẹya ara ẹrọ

Ultra-Fine lesa Aami Fojusi

Nlo imugboroja tan ina ati awọn opiti idojukọ gbigbe-giga lati ṣaṣeyọri micron tabi awọn iwọn iranran submicron, aridaju ifọkansi agbara ti o ga julọ ati iṣedede sisẹ.

Ni oye Iṣakoso System

Wa pẹlu PC ile-iṣẹ kan ati sọfitiwia wiwo ayaworan iyasọtọ ti n ṣe atilẹyin iṣẹ ti o ni ọpọlọpọ awọn ede, atunṣe paramita, iwo oju ọna irinṣẹ, ibojuwo akoko gidi, ati awọn itaniji aṣiṣe.

Agbara siseto laifọwọyi

Ṣe atilẹyin G-koodu ati agbewọle CAD pẹlu iran ipa-ọna adaṣe fun iwọnwọn ati awọn ẹya idiju ti a ṣe adani, ṣiṣatunṣe opo gigun ti apẹrẹ-si-ṣelọpọ.

Ni kikun asefara paramita

Faye gba isọdi ti awọn ipilẹ bọtini bii iwọn ila opin iho, ijinle, igun, iyara ọlọjẹ, igbohunsafẹfẹ, ati iwọn pulse fun ọpọlọpọ awọn ohun elo ati awọn sisanra.

Agbegbe Ooru Ti Kolu Kekere (HAZ)

Nlo kukuru tabi ultrashort pulse lasers (iyan) lati dinku itanka gbona ati ṣe idiwọ awọn ami sisun, awọn dojuijako, tabi ibajẹ igbekalẹ.

Ipele Išipopada XYZ Di-giga

Ni ipese pẹlu awọn modulu išipopada konge XYZ pẹlu atunwi <± 2μm, ni idaniloju aitasera ati deede titete ni microstructuring.

Ayika Ayika

Dara fun awọn agbegbe ile-iṣẹ mejeeji ati awọn agbegbe yàrá pẹlu awọn ipo aipe ti 18 ° C-28 ° C ati 30% – 60% ọriniinitutu.

Idiwon Electrical Ipese

Standard 220V / 50Hz / 10A ipese agbara, ni ibamu pẹlu Kannada ati julọ okeere itanna awọn ajohunše fun gun-igba iduroṣinṣin.

Awọn agbegbe Ohun elo

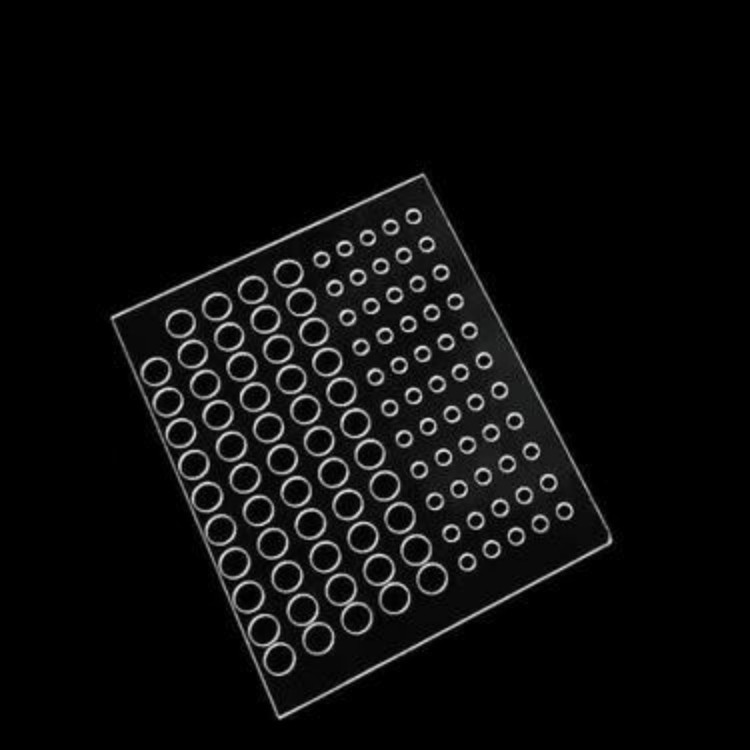

Diamond Waya Yiya Kú Liluho

Pese iyipo giga, awọn iho micro-adijositabulu pẹlu iṣakoso iwọn ila opin deede, ni ilọsiwaju igbesi aye ku ni pataki ati aitasera ọja.

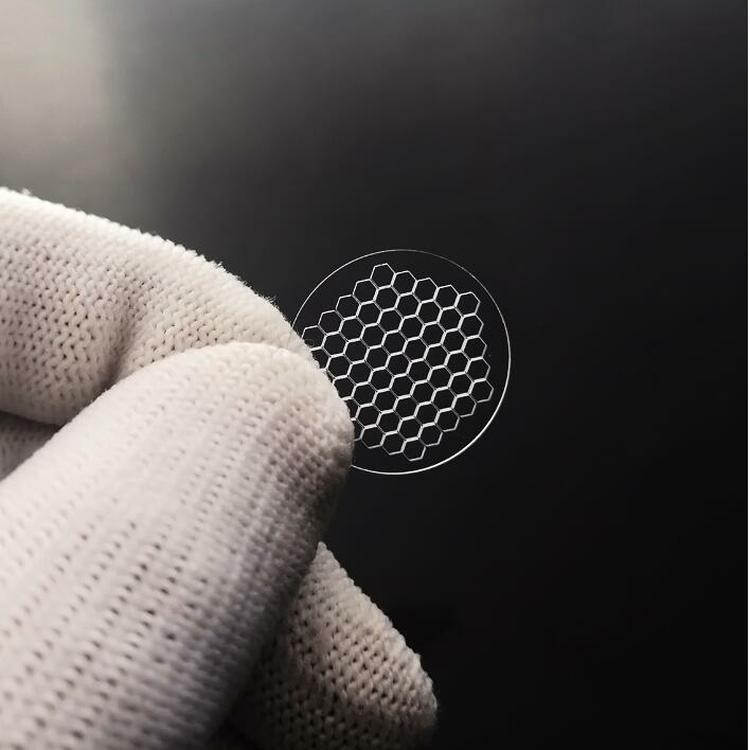

Micro-Perforation fun Silencers

Awọn ilana ipon ati aṣọ-ọṣọ micro-perforation lori irin tabi awọn ohun elo akojọpọ, apẹrẹ fun awọn ohun elo adaṣe, afẹfẹ, ati awọn ohun elo agbara.

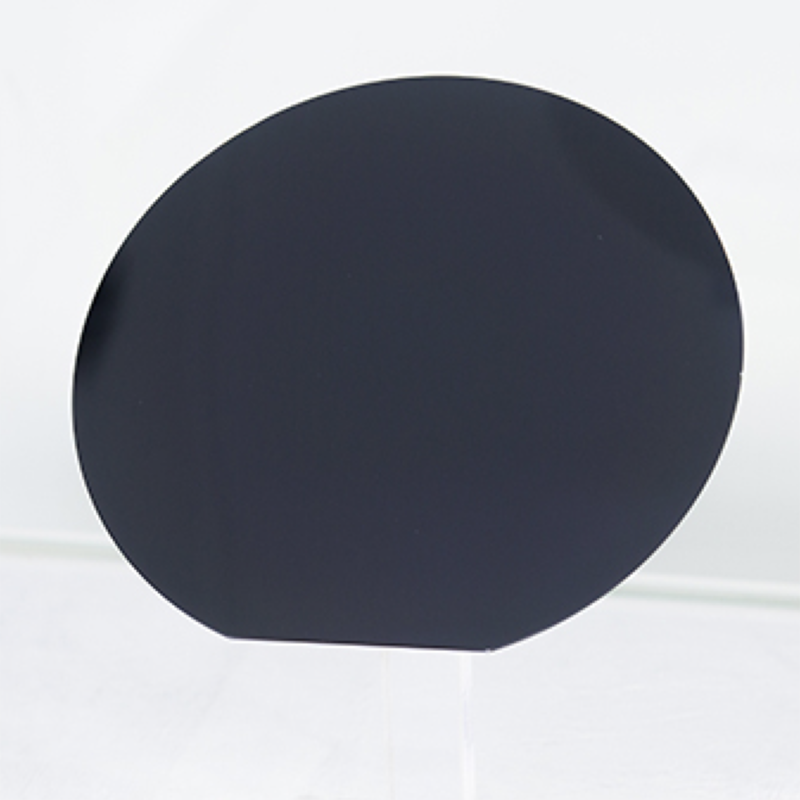

Micro-Ige ti Superhard ohun elo

Awọn ina ina lesa ti o ni agbara-giga daradara ge PCD, sapphire, awọn ohun elo amọ, ati awọn ohun elo lile-brittle miiran pẹlu pipe-giga, awọn egbegbe-ọfẹ burr.

Microfabrication fun R&D

Apẹrẹ fun awọn ile-ẹkọ giga ati awọn ile-iṣẹ iwadii lati ṣe awọn microchannels, microneedles, ati awọn ẹya opitika micro-optical pẹlu atilẹyin fun idagbasoke adani.

Ìbéèrè&A

Q1: Awọn ohun elo wo le ṣe ilana eto naa?

A1: O ṣe atilẹyin sisẹ ti diamond adayeba, PCD, oniyebiye, irin alagbara, irin, awọn ohun elo amọ, gilasi, ati awọn ohun elo ultra-lile tabi awọn ohun elo giga-giga.

Q2: Ṣe o ṣe atilẹyin liluho dada 3D?

A2: Iyan 5-axis module atilẹyin eka 3D dada machining, o dara fun alaibamu awọn ẹya ara bi molds ati turbine abe.

Q3: Njẹ orisun laser le rọpo tabi ṣe adani?

A3: Atilẹyin iyipada pẹlu agbara oriṣiriṣi tabi awọn laser gigun gigun, gẹgẹbi awọn lasers fiber tabi femtosecond/picosecond lasers, atunto fun awọn ibeere rẹ.

Q4: Bawo ni MO ṣe le gba atilẹyin imọ-ẹrọ ati iṣẹ lẹhin-tita?

A4: A nfun awọn iwadii aisan latọna jijin, itọju onsite, ati rirọpo awọn ẹya ara ẹrọ. Gbogbo awọn ọna ṣiṣe pẹlu atilẹyin ọja ni kikun ati awọn idii atilẹyin imọ-ẹrọ.

Alaye aworan atọka