4H-N HPSI SiC wafer 6H-N 6H-P 3C-N SiC Epitaxial wafer fun MOS tabi SBD

SiC Sobusitireti SiC Epi-wafer Brief

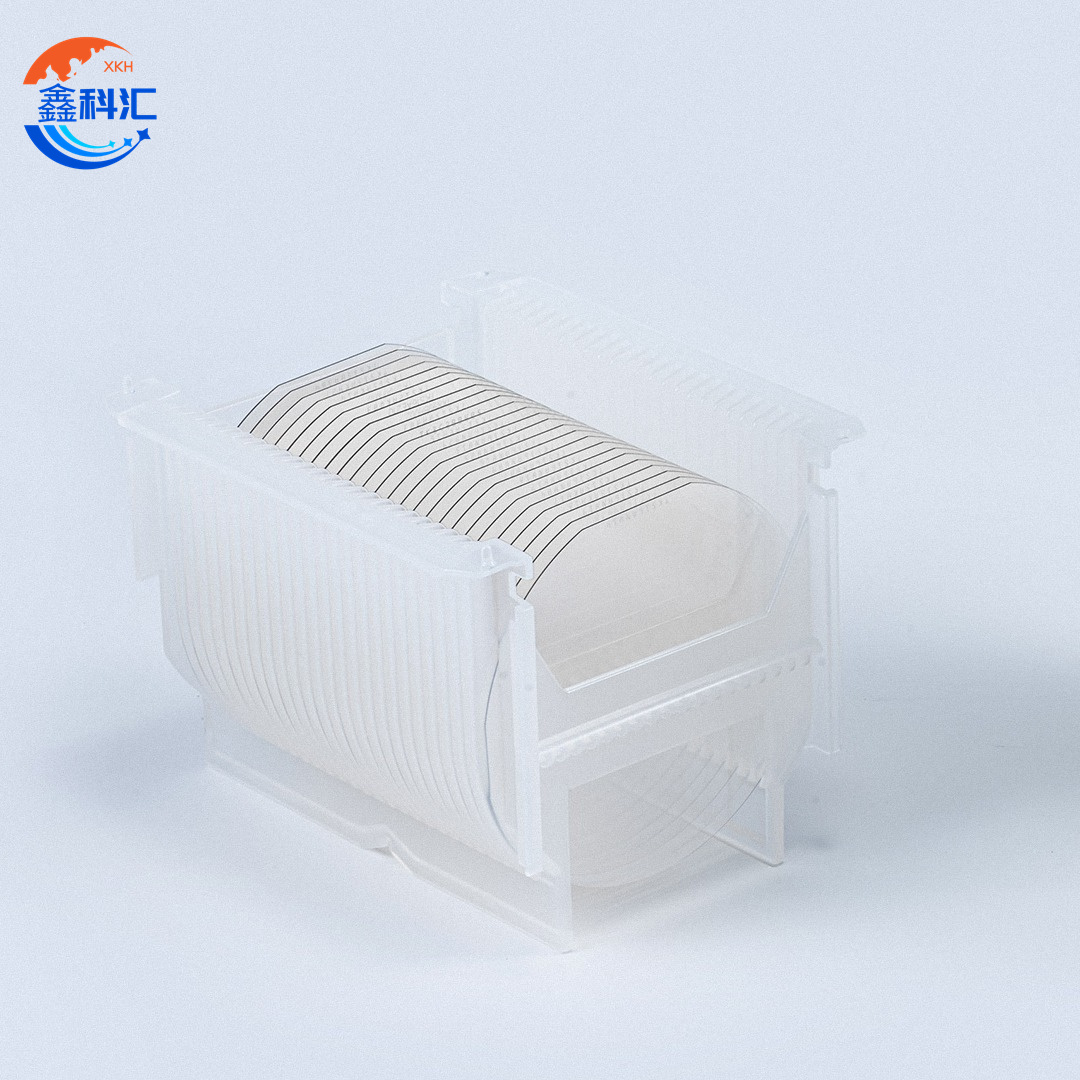

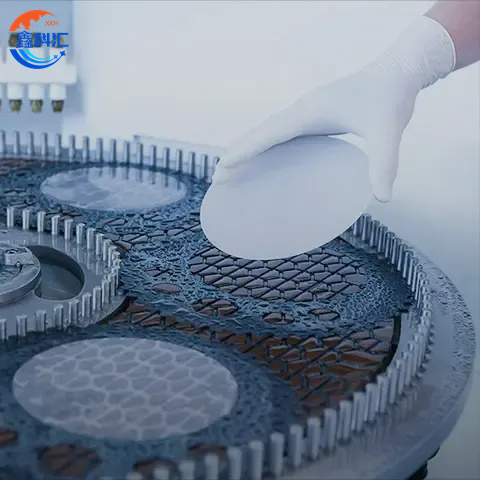

A nfunni ni kikun portfolio ti awọn sobusitireti SiC didara giga ati awọn wafers sic ni ọpọlọpọ awọn oriṣi polytypes ati awọn profaili doping-pẹlu 4H-N (n-type conductive), 4H-P (p-type conductive), 4H-HPSI (ga-mimọ ologbele-insulating), ati 6H-P (p-type conductive) ″ lati gbogbo awọn iwọn ila opin, 8 ati 6. ọna soke si 12 ″. Ni ikọja awọn sobusitireti igboro, awọn iṣẹ idagbasoke epi wafer ti a ṣafikun iye wa ṣe jiṣẹ awọn wafers epitaxial (epi) pẹlu sisanra iṣakoso ni wiwọ (1–20 µm), awọn ifọkansi doping, ati awọn iwuwo abawọn.

Sic wafer kọọkan ati epi wafer gba ayewo laini lile (iwuwo micropipe <0.1 cm⁻², roughness dada Ra <0.2 nm) ati abuda itanna ni kikun (CV, aworan agbaye resistivity) lati rii daju isokan gara ati iṣẹ ṣiṣe. Boya ti a lo fun awọn modulu itanna eleto, awọn amplifiers RF-igbohunsafẹfẹ giga, tabi awọn ẹrọ optoelectronic (Awọn LED, awọn olutọpa fọto), sobusitireti SiC wa ati awọn laini ọja epi wafer pese igbẹkẹle, iduroṣinṣin igbona, ati agbara didenukole ti o nilo nipasẹ awọn ohun elo ibeere julọ loni.

SiC Sobusitireti 4H-N iru awọn ohun-ini ati ohun elo

-

4H-N SiC sobusitireti Polytype (Hexagonal) Be

Iwọn bandgap ti ~ 3.26 eV ṣe idaniloju iṣẹ itanna iduroṣinṣin ati agbara ti o gbona labẹ iwọn otutu ati awọn ipo aaye-giga.

-

SiC sobusitiretiN-Iru Doping

Doping nitrogen ti a ṣakoso ni deede jẹ ki awọn ifọkansi ti ngbe lati 1 × 10¹⁶ si 1 × 10¹⁹ cm⁻³ ati awọn ohun elo elekitironi iwọn otutu ti yara to ~900 cm²/V·s, idinku awọn adanu ipadanu.

-

SiC sobusitiretiWide Resistivity & Aṣọkan

Iwọn resistivity to wa ti 0.01–10 Ω·cm ati awọn sisanra wafer ti 350–650 µm pẹlu ifarada ± 5% ni mejeeji doping ati sisanra—o dara fun iṣelọpọ ẹrọ agbara-giga.

-

SiC sobusitiretiÌwọ̀n Àìpé Kekere

iwuwo Micropipe <0.1 cm⁻² ati iwuwo dislocation basal-ofurufu <500 cm⁻², jiṣẹ> 99% ikore ohun elo ati iduroṣinṣin kristali ti o ga julọ.

- SiC sobusitiretiIyatọ Gbona Conductivity

Imudara ti o gbona titi di ~ 370 W / m · K ṣe iranlọwọ yiyọkuro ooru daradara, igbelaruge igbẹkẹle ẹrọ ati iwuwo agbara.

-

SiC sobusitiretiAwọn ohun elo afojusun

SiC MOSFETs, Schottky diodes, awọn modulu agbara ati awọn ẹrọ RF fun awọn awakọ ọkọ-itanna, awọn oluyipada oorun, awọn awakọ ile-iṣẹ, awọn ọna isunki, ati awọn ọja agbara-itanna miiran ti n beere.

6inch 4H-N iru SiC wafer ká sipesifikesonu | ||

| Ohun ini | Odo MPD Itejade (Ipele Z) | Idiwon Ite (D ite) |

| Ipele | Odo MPD Itejade (Ipele Z) | Idiwon Ite (D ite) |

| Iwọn opin | 149,5 mm - 150,0 mm | 149,5 mm - 150,0 mm |

| Poly-Iru | 4H | 4H |

| Sisanra | 350 µm ± 15 µm | 350 µm ± 25 µm |

| Wafer Iṣalaye | Pa axis: 4.0° si <1120> ± 0.5° | Pa axis: 4.0° si <1120> ± 0.5° |

| Iwuwo Micropipe | ≤ 0.2 cm² | ≤ 15 cm² |

| Resistivity | 0.015 - 0.024 Ω · cm | 0.015 - 0.028 Ω · cm |

| Primary Flat Iṣalaye | [10-10] ± 50° | [10-10] ± 50° |

| Primary Flat Gigun | 475 mm ± 2,0 mm | 475 mm ± 2,0 mm |

| Iyasoto eti | 3 mm | 3 mm |

| LTV/TIV / Teriba / Warp | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Irora | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5nm |

| Eti dojuijako Nipa Ga kikankikan Light | Akopọ ipari ≤ 20 mm ipari ẹyọkan ≤ 2 mm | Akopọ ipari ≤ 20 mm ipari ẹyọkan ≤ 2 mm |

| Hex farahan Nipa High kikankikan Light | Agbegbe akojọpọ ≤ 0.05% | Agbegbe akojọpọ ≤ 0.1% |

| Awọn agbegbe Polytype Nipa Imọlẹ Kikan Giga | Agbegbe akojọpọ ≤ 0.05% | Agbegbe akojọpọ ≤ 3% |

| Visual Erogba Ifisi | Agbegbe akojọpọ ≤ 0.05% | Agbegbe akojọpọ ≤ 5% |

| Silicon Surface Scratches Nipa Giga kikankikan Light | Ipari ipari ≤ 1 iwọn ila opin wafer | |

| Awọn eerun eti Nipa Imọlẹ Imọlẹ giga | Ko si idasilẹ ≥ 0.2 mm fifẹ ati ijinle | 7 laaye, ≤ 1 mm kọọkan |

| Threading dabaru Dislocation | <500 cm³ | <500 cm³ |

| Ohun alumọni dada kontaminesonu Nipa High kikankikan Light | ||

| Iṣakojọpọ | Kasẹti-wafer pupọ Tabi Apoti Wafer Nikan | Kasẹti-wafer pupọ Tabi Apoti Wafer Nikan |

8inch 4H-N iru SiC wafer ká sipesifikesonu | ||

| Ohun ini | Odo MPD Itejade (Ipele Z) | Idiwon Ite (D ite) |

| Ipele | Odo MPD Itejade (Ipele Z) | Idiwon Ite (D ite) |

| Iwọn opin | 199,5 mm - 200,0 mm | 199,5 mm - 200,0 mm |

| Poly-Iru | 4H | 4H |

| Sisanra | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Wafer Iṣalaye | 4.0° si <110> ± 0.5° | 4.0° si <110> ± 0.5° |

| Iwuwo Micropipe | ≤ 0.2 cm² | ≤ 5 cm² |

| Resistivity | 0.015 - 0.025 Ω · cm | 0.015 - 0.028 Ω · cm |

| Noble Iṣalaye | ||

| Iyasoto eti | 3 mm | 3 mm |

| LTV/TIV / Teriba / Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Irora | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5nm |

| Eti dojuijako Nipa Ga kikankikan Light | Akopọ ipari ≤ 20 mm ipari ẹyọkan ≤ 2 mm | Akopọ ipari ≤ 20 mm ipari ẹyọkan ≤ 2 mm |

| Hex farahan Nipa High kikankikan Light | Agbegbe akojọpọ ≤ 0.05% | Agbegbe akojọpọ ≤ 0.1% |

| Awọn agbegbe Polytype Nipa Imọlẹ Kikan Giga | Agbegbe akojọpọ ≤ 0.05% | Agbegbe akojọpọ ≤ 3% |

| Visual Erogba Ifisi | Agbegbe akojọpọ ≤ 0.05% | Agbegbe akojọpọ ≤ 5% |

| Silicon Surface Scratches Nipa Giga kikankikan Light | Ipari ipari ≤ 1 iwọn ila opin wafer | |

| Awọn eerun eti Nipa Imọlẹ Imọlẹ giga | Ko si idasilẹ ≥ 0.2 mm fifẹ ati ijinle | 7 laaye, ≤ 1 mm kọọkan |

| Threading dabaru Dislocation | <500 cm³ | <500 cm³ |

| Ohun alumọni dada kontaminesonu Nipa High kikankikan Light | ||

| Iṣakojọpọ | Kasẹti-wafer pupọ Tabi Apoti Wafer Nikan | Kasẹti-wafer pupọ Tabi Apoti Wafer Nikan |

4H-SiC jẹ ohun elo ti o ga julọ ti a lo fun ẹrọ itanna agbara, awọn ẹrọ RF, ati awọn ohun elo iwọn otutu giga. “4H” naa n tọka si igbekalẹ gara, eyiti o jẹ hexagonal, ati “N” tọkasi iru doping ti a lo lati mu iṣẹ ohun elo naa dara si.

Awọn4H-SiCIru ni a maa n lo fun:

Itanna Agbara:Ti a lo ninu awọn ẹrọ bii diodes, MOSFETs, ati IGBTs fun awọn ọkọ oju-irin ina mọnamọna, ẹrọ ile-iṣẹ, ati awọn eto agbara isọdọtun.

5G ọna ẹrọ:Pẹlu ibeere 5G fun igbohunsafẹfẹ giga-giga ati awọn paati ṣiṣe-giga, agbara SiC lati mu awọn foliteji giga ati ṣiṣẹ ni awọn iwọn otutu giga jẹ ki o jẹ apẹrẹ fun awọn amplifiers agbara ibudo ipilẹ ati awọn ẹrọ RF.

Awọn ọna Agbara Oorun:Awọn ohun-ini mimu agbara ti o dara julọ ti SiC jẹ apẹrẹ fun awọn oluyipada fọtovoltaic (agbara oorun) ati awọn oluyipada.

Awọn ọkọ ina (EVS):SiC ti wa ni lilo pupọ ni EV powertrains fun iyipada agbara ti o munadoko diẹ sii, iran ooru kekere, ati awọn iwuwo agbara ti o ga julọ.

SiC Sobusitireti 4H Ologbele-Idabobo iru ká ini ati ohun elo

Awọn ohun-ini:

-

Awọn ilana iṣakoso iwuwo-ọfẹ Micropipe: Ṣe idaniloju isansa ti awọn micropipes, imudarasi didara sobusitireti.

-

Monocrystalline Iṣakoso imuposi: Ṣe iṣeduro ilana okuta kan kan fun awọn ohun elo imudara.

-

Inclusions Iṣakoso imuposi: Dinku wiwa awọn aimọ tabi awọn ifisi, ni idaniloju sobusitireti mimọ.

-

Resistivity Iṣakoso imuposi: Gba fun iṣakoso kongẹ ti resistivity itanna, eyiti o ṣe pataki fun iṣẹ ẹrọ.

-

Ilana aimọ ati awọn ilana iṣakoso: Awọn ilana ati fi opin si ifihan ti awọn impurities lati ṣetọju iduroṣinṣin sobusitireti.

-

Sobusitireti igbese Iṣakoso awọn ilana: Pese iṣakoso deede lori iwọn igbese, aridaju aitasera kọja sobusitireti

6Inch 4H-ologbele SiC sobusitireti sipesifikesonu | ||

| Ohun ini | Odo MPD Itejade (Ipele Z) | Idiwon Ite (D ite) |

| Iwọn (mm) | 145 mm - 150 mm | 145 mm - 150 mm |

| Poly-Iru | 4H | 4H |

| Sisanra (um) | 500 ± 15 | 500 ± 25 |

| Wafer Iṣalaye | Lori ipo: ± 0.0001 ° | Lori ipo: ± 0.05° |

| Iwuwo Micropipe | ≤ 15 cm-2 | ≤ 15 cm-2 |

| Resistivity (Ωcm) | ≥ 10E3 | ≥ 10E3 |

| Primary Flat Iṣalaye | (0-10) ° ± 5,0 ° | (10-10) ° ± 5,0 ° |

| Primary Flat Gigun | Ogbontarigi | Ogbontarigi |

| Iyasoto eti (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / Ekan / Warp | ≤ 3µm | ≤ 3µm |

| Irora | Polish Ra ≤ 1.5 µm | Polish Ra ≤ 1.5 µm |

| Awọn eerun eti Nipa Imọlẹ Imọlẹ giga | ≤20 µm | ≤ 60µm |

| Ooru farahan Nipa High kikankikan Light | Akopọ ≤ 0.05% | Akopọ ≤ 3% |

| Awọn agbegbe Polytype Nipa Imọlẹ Kikan Giga | Awọn ifisi Erogba wiwo ≤ 0.05% | Akopọ ≤ 3% |

| Silicon Surface Scratches Nipa Giga kikankikan Light | ≤ 0.05% | Akopọ ≤ 4% |

| Awọn Chips Edge Nipa Imọlẹ Kikan Giga (Iwọn) | Ko Gbigbanilaaye> 02 mm Iwọn ati Ijinle | Ko Gbigbanilaaye> 02 mm Iwọn ati Ijinle |

| The Aiding dabaru Dilation | ≤ 500 µm | ≤ 500 µm |

| Ohun alumọni dada kontaminesonu Nipa High kikankikan Light | ≤ 1 x 10^5 | ≤ 1 x 10^5 |

| Iṣakojọpọ | Kasẹti-wafer pupọ tabi Apoti Wafer Kanṣoṣo | Kasẹti-wafer pupọ tabi Apoti Wafer Kanṣoṣo |

4-Inch 4H-Semi Insulating SiC sobusitireti Specification

| Paramita | Odo MPD Itejade (Ipele Z) | Idiwon Ite (D ite) |

|---|---|---|

| Ti ara Properties | ||

| Iwọn opin | 99,5 mm - 100,0 mm | 99,5 mm - 100,0 mm |

| Poly-Iru | 4H | 4H |

| Sisanra | 500 μm ± 15 μm | 500 μm ± 25 μm |

| Wafer Iṣalaye | Lori ipo: <600h> 0.5° | Lori ipo: <000h> 0.5° |

| Itanna Properties | ||

| Ìwúwo Micropipe (MPD) | ≤1 cm⁻² | ≤15 cm⁻² |

| Resistivity | ≥150 Ω·cm | ≥1.5 Ω·cm |

| Jiometirika Tolerances | ||

| Primary Flat Iṣalaye | (0x10) ± 5.0 ° | (0x10) ± 5.0 ° |

| Primary Flat Gigun | 52,5 mm ± 2,0 mm | 52,5 mm ± 2,0 mm |

| Secondary Flat Gigun | 18,0 mm ± 2,0 mm | 18,0 mm ± 2,0 mm |

| Atẹle Flat Iṣalaye | 90° CW lati alapin Prime ± 5.0° (Si koju soke) | 90° CW lati alapin Prime ± 5.0° (Si koju soke) |

| Iyasoto eti | 3 mm | 3 mm |

| LTV / TTV / Teriba / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10 μm / ≤15 μm / ≤25 μm / ≤40 μm |

| Dada Didara | ||

| Roughness Dada (Polish Ra) | ≤1 nm | ≤1 nm |

| Roughness Dada (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| Awọn dojuijako eti (Imọlẹ-kikankikan) | Ko gba laaye | Ipari ipari ≥10 mm, kiraki ẹyọkan ≤2 mm |

| Awọn abawọn Awo Hexagonal | ≤0.05% agbegbe akojo | ≤0.1% agbegbe akopọ |

| Awọn agbegbe Ifisi Polytype | Ko gba laaye | ≤1% agbegbe akopọ |

| Visual Erogba Ifisi | ≤0.05% agbegbe akojo | ≤1% agbegbe akopọ |

| Silikoni dada scratches | Ko gba laaye | ≤1 wafer iwọn ila opin akojo ipari |

| Awọn eerun eti | Ko gba laaye (≥0.2 mm fifẹ/ijinle) | ≤5 awọn eerun (ọkọọkan ≤1 mm) |

| Ohun alumọni dada koto | Lai so ni pato | Lai so ni pato |

| Iṣakojọpọ | ||

| Iṣakojọpọ | Kasẹti-wafer pupọ tabi eiyan wafer ẹyọkan | Olona-wafer kasẹti tabi |

Ohun elo:

AwọnSiC 4H Ologbele-Idabobo sobsitiretiti wa ni nipataki lo ni ga-agbara ati ki o ga-igbohunsafẹfẹ ẹrọ itanna, paapa ninu awọnRF aaye. Awọn sobusitireti wọnyi ṣe pataki fun ọpọlọpọ awọn ohun elo pẹlumakirowefu ibaraẹnisọrọ awọn ọna šiše, Rada orun alakoso, atialailowaya itanna aṣawari. Imudara igbona giga wọn ati awọn abuda itanna to dara julọ jẹ ki wọn jẹ apẹrẹ fun awọn ohun elo eletan ni ẹrọ itanna agbara ati awọn eto ibaraẹnisọrọ.

SiC epi wafer 4H-N iru awọn ohun-ini ati ohun elo

SiC 4H-N Iru Epi Wafer Awọn ohun-ini ati Awọn ohun elo

Awọn ohun-ini ti SiC 4H-N Iru Epi Wafer:

Ohun elo

SiC (Silikoni Carbide): Ti a mọ fun líle ti o ṣe pataki, imudani ti o gbona, ati awọn ohun-ini itanna to dara julọ, SiC jẹ apẹrẹ fun awọn ẹrọ itanna ti o ga julọ.

4H-SiC Polytype: Awọn polytype 4H-SiC ni a mọ fun ṣiṣe giga rẹ ati iduroṣinṣin ni awọn ohun elo itanna.

N-iru Doping: N-type doping (doped with nitrogen) n pese iṣipopada elekitironi ti o dara julọ, ṣiṣe SiC ti o dara fun awọn ohun elo giga-igbohunsafẹfẹ ati agbara-giga.

Imudara Ooru Ga:

SiC wafers ni ga ju gbona iba ina elekitiriki, ojo melo orisirisi lati120–200 W/m·K, gbigba wọn laaye lati ṣakoso ooru ni imunadoko ni awọn ẹrọ agbara-giga bi transistors ati diodes.

Ibadi nla:

Pẹlu kan bandgap ti3.26 eV, 4H-SiC le ṣiṣẹ ni awọn foliteji ti o ga julọ, awọn igbohunsafẹfẹ, ati awọn iwọn otutu ti a fiwe si awọn ohun elo ti o da lori ohun alumọni ti aṣa, ti o jẹ ki o dara julọ fun ṣiṣe-giga, awọn ohun elo ti o ga julọ.

Awọn ohun-ini itanna:

SiC ká ga elekitironi arinbo ati conductivity jẹ ki o bojumu funitanna agbara, Laimu awọn iyara iyipada ni kiakia ati giga lọwọlọwọ ati agbara mimu agbara, ti o mu ki awọn eto iṣakoso agbara ti o dara julọ.

Atako ati Kemikali:

SiC jẹ ọkan ninu awọn ohun elo ti o nira julọ, keji nikan si diamond, ati pe o ni sooro pupọ si oxidation ati ipata, ti o jẹ ki o tọ ni awọn agbegbe lile.

Awọn ohun elo ti SiC 4H-N Iru Epi Wafer:

Itanna Agbara:

SiC 4H-N iru epi wafers ti wa ni o gbajumo ni lilo ninuagbara MOSFETs, Awọn IGBT, atidiodesfuniyipada agbaraninu awọn ọna šiše bioorun inverters, ina awọn ọkọ ti, atiagbara ipamọ awọn ọna šiše, laimu imudara iṣẹ ati ṣiṣe agbara.

Awọn ọkọ ina (EVS):

In ina ti nše ọkọ powertrains, motor olutona, atigbigba agbara ibudo, SiC wafers ṣe iranlọwọ lati ṣaṣeyọri ṣiṣe batiri to dara julọ, gbigba agbara yiyara, ati ilọsiwaju iṣẹ agbara gbogbogbo nitori agbara wọn lati mu agbara giga ati awọn iwọn otutu.

Awọn ọna Agbara Isọdọtun:

Oorun Inverters: SiC wafers ti wa ni lilo ninuoorun agbara awọn ọna šišefun iyipada agbara DC lati awọn panẹli oorun si AC, jijẹ ṣiṣe eto gbogbogbo ati iṣẹ ṣiṣe.

Afẹfẹ Turbines: SiC ọna ẹrọ ti wa ni oojọ ti niafẹfẹ tobaini Iṣakoso awọn ọna šiše, iṣapeye iṣelọpọ agbara ati ṣiṣe iyipada.

Ofurufu ati Aabo:

SiC wafers jẹ apẹrẹ fun lilo ninuOfurufu Electronicsatiologun ohun elo, pẹluReda awọn ọna šišeatiẹrọ itanna satẹlaiti, nibiti resistance itankalẹ giga ati iduroṣinṣin gbona jẹ pataki.

Ooru-giga ati Awọn ohun elo Igbohunsafẹfẹ giga:

SiC wafers tayọ niga-otutu itanna, lo ninuoko ofurufu enjini, oko ofurufu, atiise alapapo awọn ọna šiše, bi wọn ṣe ṣetọju iṣẹ ni awọn ipo ooru to gaju. Ni afikun, bandgap jakejado wọn gba laaye fun lilo ninuga-igbohunsafẹfẹ ohun elofẹranAwọn ẹrọ RFatimakirowefu awọn ibaraẹnisọrọ.

| 6-inch N-type epit axial sipesifikesonu | |||

| Paramita | ẹyọkan | Z-MOS | |

| Iru | Condutivity / Dopant | - | N-type / Nitrojini |

| Ifipamọ Layer | Ifipamọ Layer Sisanra | um | 1 |

| Ifarada Layer Sisanra | % | ± 20% | |

| Ifoju Layer Layer | cm-3 | 1.00E + 18 | |

| Ifarada Ifojusi Layer Layer | % | ± 20% | |

| 1st Epi Layer | Epi Layer Sisanra | um | 11.5 |

| Epi Layer Isokan Sisanra | % | ± 4% | |

| Ifarada Sisanra Awọn Layer Epi((Spec-) O pọju, min)/Spec) | % | ± 5% | |

| Epi Layer ifọkansi | cm-3 | 1E 15~ 1E 18 | |

| Ifarada Ifọkansi Epi Layer | % | 6% | |

| Ìṣọ̀kan Ifọkanbalẹ Epi Layer (σ / tumo si) | % | ≤5% | |

| Epi Layer ifọkansi Aṣọkan <(max-min)/(max+min> | % | ≤ 10% | |

| Epitaixal Wafer Apẹrẹ | Teriba | um | ≤±20 |

| IGBAGBÜ | um | ≤30 | |

| TTV | um | ≤ 10 | |

| LTV | um | ≤2 | |

| Gbogbogbo Abuda | Scratches ipari | mm | ≤30mm |

| Awọn eerun eti | - | KOSI | |

| Itumọ awọn abawọn | ≥97% (Ti a ṣe pẹlu 2*2). Awọn abawọn apaniyan pẹlu: Awọn abawọn pẹlu Micropipe / Awọn ọfin nla, Karooti, onigun mẹta | ||

| Irin idoti | awọn ọta/cm² | d f f l i ≤5E10 awọn ọta/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| Package | Iṣakojọpọ ni pato | pcs / apoti | kasẹti olona-wafer tabi eiyan wafer ẹyọkan |

| 8-inch N-type epitaxial sipesifikesonu | |||

| Paramita | ẹyọkan | Z-MOS | |

| Iru | Condutivity / Dopant | - | N-type / Nitrojini |

| Ifipamọ Layer | Ifipamọ Layer Sisanra | um | 1 |

| Ifarada Layer Sisanra | % | ± 20% | |

| Ifoju Layer Layer | cm-3 | 1.00E + 18 | |

| Ifarada Ifojusi Layer Layer | % | ± 20% | |

| 1st Epi Layer | Epi Layers Sisanra Apapọ | um | 8-12 |

| Isokan Sisanra Awọn Layer Epi (σ/itumọ) | % | ≤2.0 | |

| Ifarada Sisanra Awọn Layer Epi((Spec -Max,min)/Spec) | % | ±6 | |

| Epi Layers Apapọ Doping | cm-3 | 8E+15 ~2E+16 | |

| Aṣọkan Doping Apapọ Epi Layers (σ/tumọ) | % | ≤5 | |

| Ifarada Doping Apapọ Epi Layer ((Spec -Max, | % | ± 10.0 | |

| Epitaixal Wafer Apẹrẹ | Mi )/S) Ijagun | um | ≤50.0 |

| Teriba | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤4.0 (10mm×10mm) | |

| Gbogboogbo Awọn abuda | Scratches | - | Akopọ gigun≤ 1/2 Iwọn ila opin wafer |

| Awọn eerun eti | - | ≤2 eerun, Kọọkan rediosi≤1.5mm | |

| Dada Awọn irin Kontaminesonu | awọn ọta / cm2 | ≤5E10 awọn ọta/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| Ayẹwo Aṣiṣe | % | ≥ 96.0 (Awọn abawọn 2X2 pẹlu Micropipe / Awọn ọfin nla, Karọọti, awọn abawọn onigun mẹta, awọn isubu, Linear/IGSF-s, BPD) | |

| Dada Awọn irin Kontaminesonu | awọn ọta / cm2 | ≤5E10 awọn ọta/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| Package | Iṣakojọpọ ni pato | - | kasẹti olona-wafer tabi eiyan wafer ẹyọkan |

SiC wafer ká Q&A

Q1: Kini awọn anfani bọtini ti lilo SiC wafers lori awọn ohun alumọni ohun alumọni ti aṣa ni ẹrọ itanna agbara?

A1:

SiC wafers nfunni ni ọpọlọpọ awọn anfani bọtini lori awọn ohun alumọni ibile (Si) ni ẹrọ itanna agbara, pẹlu:

Ti o ga ṣiṣe: SiC ni bandgap ti o gbooro (3.26 eV) ni akawe si ohun alumọni (1.1 eV), gbigba awọn ẹrọ laaye lati ṣiṣẹ ni awọn foliteji giga, awọn igbohunsafẹfẹ, ati awọn iwọn otutu. Eyi nyorisi isonu agbara kekere ati ṣiṣe ti o ga julọ ni awọn eto iyipada agbara.

Ga Gbona Conductivity: SiC's thermal conductivity jẹ ti o ga julọ ju ti ohun alumọni lọ, ti o mu ki ooru ti o dara julọ ni awọn ohun elo ti o ga julọ, ti o mu ki igbẹkẹle ati igbesi aye awọn ẹrọ agbara.

Ti o ga Foliteji ati lọwọlọwọ mimu: Awọn ẹrọ SiC le mu awọn foliteji ti o ga julọ ati awọn ipele lọwọlọwọ, ṣiṣe wọn dara fun awọn ohun elo agbara-giga gẹgẹbi awọn ọkọ ayọkẹlẹ ina, awọn ọna agbara isọdọtun, ati awọn awakọ ọkọ ayọkẹlẹ ile-iṣẹ.

Iyara Yipada Yiyara: Awọn ẹrọ SiC ni awọn agbara iyipada ti o yarayara, eyi ti o ṣe alabapin si idinku agbara agbara ati iwọn eto, ṣiṣe wọn ni apẹrẹ fun awọn ohun elo igbohunsafẹfẹ giga.

Q2: Kini awọn ohun elo akọkọ ti SiC wafers ni ile-iṣẹ adaṣe?

A2:

Ninu ile-iṣẹ adaṣe, awọn wafers SiC jẹ lilo akọkọ ni:

Electric ti nše ọkọ (EV) Powertrains: SiC-orisun irinše biinvertersatiagbara MOSFETsmu ilọsiwaju ati iṣẹ ṣiṣe ti awọn ọkọ oju-irin ọkọ ina mọnamọna ṣiṣẹ nipasẹ ṣiṣe awọn iyara yiyi yiyara ati iwuwo agbara ti o ga julọ. Eyi nyorisi igbesi aye batiri to gun ati iṣẹ ṣiṣe ọkọ gbogbogbo to dara julọ.

Awọn ṣaja lori-ọkọ: Awọn ẹrọ SiC ṣe iranlọwọ lati mu ilọsiwaju ti awọn ọna ṣiṣe gbigba agbara lori-ọkọ nipa fifun awọn akoko gbigba agbara ni kiakia ati iṣakoso igbona ti o dara julọ, eyiti o ṣe pataki fun awọn EVs lati ṣe atilẹyin awọn ibudo gbigba agbara giga.

Awọn ọna iṣakoso Batiri (BMS): SiC ọna ẹrọ se awọn ṣiṣe tibatiri isakoso awọn ọna šiše, gbigba fun ilana foliteji to dara julọ, mimu agbara ti o ga julọ, ati igbesi aye batiri to gun.

Awọn oluyipada DC-DC: SiC wafers ti wa ni lilo ninuDC-DC converterslati ṣe iyipada agbara DC-giga-giga si agbara DC kekere-kekere daradara siwaju sii, eyiti o ṣe pataki ninu awọn ọkọ ina mọnamọna lati ṣakoso agbara lati batiri si ọpọlọpọ awọn paati ninu ọkọ.

Išẹ ti o ga julọ ti SiC ni giga-foliteji, iwọn otutu giga, ati awọn ohun elo ṣiṣe ti o ga julọ jẹ ki o ṣe pataki fun iyipada ile-iṣẹ ọkọ ayọkẹlẹ si iṣipopada ina.

6inch 4H-N iru SiC wafer ká sipesifikesonu | ||

| Ohun ini | Odo MPD Itejade (Ipele Z) | Idiwon Ite (D ite) |

| Ipele | Odo MPD Itejade (Ipele Z) | Idiwon Ite (D ite) |

| Iwọn opin | 149,5 mm - 150,0 mm | 149,5 mm - 150,0 mm |

| Poly-Iru | 4H | 4H |

| Sisanra | 350 µm ± 15 µm | 350 µm ± 25 µm |

| Wafer Iṣalaye | Pa axis: 4.0° si <1120> ± 0.5° | Pa axis: 4.0° si <1120> ± 0.5° |

| Iwuwo Micropipe | ≤ 0.2 cm² | ≤ 15 cm² |

| Resistivity | 0.015 – 0.024 Ω · cm | 0.015 – 0.028 Ω · cm |

| Primary Flat Iṣalaye | [10-10] ± 50° | [10-10] ± 50° |

| Primary Flat Gigun | 475 mm ± 2,0 mm | 475 mm ± 2,0 mm |

| Iyasoto eti | 3 mm | 3 mm |

| LTV/TIV / Teriba / Warp | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Irora | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5nm |

| Eti dojuijako Nipa Ga kikankikan Light | Akopọ ipari ≤ 20 mm ipari ẹyọkan ≤ 2 mm | Akopọ ipari ≤ 20 mm ipari ẹyọkan ≤ 2 mm |

| Hex farahan Nipa High kikankikan Light | Agbegbe akojọpọ ≤ 0.05% | Agbegbe akojọpọ ≤ 0.1% |

| Awọn agbegbe Polytype Nipa Imọlẹ Kikan Giga | Agbegbe akojọpọ ≤ 0.05% | Agbegbe akojọpọ ≤ 3% |

| Visual Erogba Ifisi | Agbegbe akojọpọ ≤ 0.05% | Agbegbe akojọpọ ≤ 5% |

| Silicon Surface Scratches Nipa Giga kikankikan Light | Ipari ipari ≤ 1 iwọn ila opin wafer | |

| Awọn eerun eti Nipa Imọlẹ Imọlẹ giga | Ko si idasilẹ ≥ 0.2 mm fifẹ ati ijinle | 7 laaye, ≤ 1 mm kọọkan |

| Threading dabaru Dislocation | <500 cm³ | <500 cm³ |

| Ohun alumọni dada kontaminesonu Nipa High kikankikan Light | ||

| Iṣakojọpọ | Kasẹti-wafer pupọ Tabi Apoti Wafer Nikan | Kasẹti-wafer pupọ Tabi Apoti Wafer Nikan |

8inch 4H-N iru SiC wafer ká sipesifikesonu | ||

| Ohun ini | Odo MPD Itejade (Ipele Z) | Idiwon Ite (D ite) |

| Ipele | Odo MPD Itejade (Ipele Z) | Idiwon Ite (D ite) |

| Iwọn opin | 199,5 mm - 200,0 mm | 199,5 mm - 200,0 mm |

| Poly-Iru | 4H | 4H |

| Sisanra | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Wafer Iṣalaye | 4.0° si <110> ± 0.5° | 4.0° si <110> ± 0.5° |

| Iwuwo Micropipe | ≤ 0.2 cm² | ≤ 5 cm² |

| Resistivity | 0.015 – 0.025 Ω · cm | 0.015 – 0.028 Ω · cm |

| Noble Iṣalaye | ||

| Iyasoto eti | 3 mm | 3 mm |

| LTV/TIV / Teriba / Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Irora | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5nm |

| Eti dojuijako Nipa Ga kikankikan Light | Akopọ ipari ≤ 20 mm ipari ẹyọkan ≤ 2 mm | Akopọ ipari ≤ 20 mm ipari ẹyọkan ≤ 2 mm |

| Hex farahan Nipa High kikankikan Light | Agbegbe akojọpọ ≤ 0.05% | Agbegbe akojọpọ ≤ 0.1% |

| Awọn agbegbe Polytype Nipa Imọlẹ Kikan Giga | Agbegbe akojọpọ ≤ 0.05% | Agbegbe akojọpọ ≤ 3% |

| Visual Erogba Ifisi | Agbegbe akojọpọ ≤ 0.05% | Agbegbe akojọpọ ≤ 5% |

| Silicon Surface Scratches Nipa Giga kikankikan Light | Ipari ipari ≤ 1 iwọn ila opin wafer | |

| Awọn eerun eti Nipa Imọlẹ Imọlẹ giga | Ko si idasilẹ ≥ 0.2 mm fifẹ ati ijinle | 7 laaye, ≤ 1 mm kọọkan |

| Threading dabaru Dislocation | <500 cm³ | <500 cm³ |

| Ohun alumọni dada kontaminesonu Nipa High kikankikan Light | ||

| Iṣakojọpọ | Kasẹti-wafer pupọ Tabi Apoti Wafer Nikan | Kasẹti-wafer pupọ Tabi Apoti Wafer Nikan |

6Inch 4H-ologbele SiC sobusitireti sipesifikesonu | ||

| Ohun ini | Odo MPD Itejade (Ipele Z) | Idiwon Ite (D ite) |

| Iwọn (mm) | 145 mm - 150 mm | 145 mm - 150 mm |

| Poly-Iru | 4H | 4H |

| Sisanra (um) | 500 ± 15 | 500 ± 25 |

| Wafer Iṣalaye | Lori ipo: ± 0.0001 ° | Lori ipo: ± 0.05° |

| Iwuwo Micropipe | ≤ 15 cm-2 | ≤ 15 cm-2 |

| Resistivity (Ωcm) | ≥ 10E3 | ≥ 10E3 |

| Primary Flat Iṣalaye | (0-10) ° ± 5,0 ° | (10-10) ° ± 5,0 ° |

| Primary Flat Gigun | Ogbontarigi | Ogbontarigi |

| Iyasoto eti (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / Ekan / Warp | ≤ 3µm | ≤ 3µm |

| Irora | Polish Ra ≤ 1.5 µm | Polish Ra ≤ 1.5 µm |

| Awọn eerun eti Nipa Imọlẹ Imọlẹ giga | ≤20 µm | ≤ 60µm |

| Ooru farahan Nipa High kikankikan Light | Akopọ ≤ 0.05% | Akopọ ≤ 3% |

| Awọn agbegbe Polytype Nipa Imọlẹ Kikan Giga | Awọn ifisi Erogba wiwo ≤ 0.05% | Akopọ ≤ 3% |

| Silicon Surface Scratches Nipa Giga kikankikan Light | ≤ 0.05% | Akopọ ≤ 4% |

| Awọn Chips Edge Nipa Imọlẹ Kikan Giga (Iwọn) | Ko Gbigbanilaaye> 02 mm Iwọn ati Ijinle | Ko Gbigbanilaaye> 02 mm Iwọn ati Ijinle |

| The Aiding dabaru Dilation | ≤ 500 µm | ≤ 500 µm |

| Ohun alumọni dada kontaminesonu Nipa High kikankikan Light | ≤ 1 x 10^5 | ≤ 1 x 10^5 |

| Iṣakojọpọ | Kasẹti-wafer pupọ tabi Apoti Wafer Kanṣoṣo | Kasẹti-wafer pupọ tabi Apoti Wafer Kanṣoṣo |

4-Inch 4H-Semi Insulating SiC sobusitireti Specification

| Paramita | Odo MPD Itejade (Ipele Z) | Idiwon Ite (D ite) |

|---|---|---|

| Ti ara Properties | ||

| Iwọn opin | 99,5 mm - 100,0 mm | 99,5 mm - 100,0 mm |

| Poly-Iru | 4H | 4H |

| Sisanra | 500 μm ± 15 μm | 500 μm ± 25 μm |

| Wafer Iṣalaye | Lori ipo: <600h> 0.5° | Lori ipo: <000h> 0.5° |

| Itanna Properties | ||

| Ìwúwo Micropipe (MPD) | ≤1 cm⁻² | ≤15 cm⁻² |

| Resistivity | ≥150 Ω·cm | ≥1.5 Ω·cm |

| Jiometirika Tolerances | ||

| Primary Flat Iṣalaye | (0× 10) ± 5,0 ° | (0× 10) ± 5,0 ° |

| Primary Flat Gigun | 52,5 mm ± 2,0 mm | 52,5 mm ± 2,0 mm |

| Secondary Flat Gigun | 18,0 mm ± 2,0 mm | 18,0 mm ± 2,0 mm |

| Atẹle Flat Iṣalaye | 90° CW lati alapin Prime ± 5.0° (Si koju soke) | 90° CW lati alapin Prime ± 5.0° (Si koju soke) |

| Iyasoto eti | 3 mm | 3 mm |

| LTV / TTV / Teriba / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10 μm / ≤15 μm / ≤25 μm / ≤40 μm |

| Dada Didara | ||

| Roughness Dada (Polish Ra) | ≤1 nm | ≤1 nm |

| Roughness Dada (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| Awọn dojuijako eti (Imọlẹ-kikankikan) | Ko gba laaye | Ipari ipari ≥10 mm, kiraki ẹyọkan ≤2 mm |

| Awọn abawọn Awo Hexagonal | ≤0.05% agbegbe akojo | ≤0.1% agbegbe akopọ |

| Awọn agbegbe Ifisi Polytype | Ko gba laaye | ≤1% agbegbe akopọ |

| Visual Erogba Ifisi | ≤0.05% agbegbe akojo | ≤1% agbegbe akopọ |

| Silikoni dada scratches | Ko gba laaye | ≤1 wafer iwọn ila opin akojo ipari |

| Awọn eerun eti | Ko gba laaye (≥0.2 mm fifẹ/ijinle) | ≤5 awọn eerun (ọkọọkan ≤1 mm) |

| Ohun alumọni dada koto | Lai so ni pato | Lai so ni pato |

| Iṣakojọpọ | ||

| Iṣakojọpọ | Kasẹti-wafer pupọ tabi eiyan wafer ẹyọkan | Olona-wafer kasẹti tabi |

| 6-inch N-type epit axial sipesifikesonu | |||

| Paramita | ẹyọkan | Z-MOS | |

| Iru | Condutivity / Dopant | - | N-type / Nitrojini |

| Ifipamọ Layer | Ifipamọ Layer Sisanra | um | 1 |

| Ifarada Layer Sisanra | % | ± 20% | |

| Ifoju Layer Layer | cm-3 | 1.00E + 18 | |

| Ifarada Ifojusi Layer Layer | % | ± 20% | |

| 1st Epi Layer | Epi Layer Sisanra | um | 11.5 |

| Epi Layer Isokan Sisanra | % | ± 4% | |

| Ifarada Sisanra Awọn Layer Epi((Spec-) O pọju, min)/Spec) | % | ± 5% | |

| Epi Layer ifọkansi | cm-3 | 1E 15~ 1E 18 | |

| Ifarada Ifọkansi Epi Layer | % | 6% | |

| Ìṣọ̀kan Ifọkanbalẹ Epi Layer (σ / tumo si) | % | ≤5% | |

| Epi Layer ifọkansi Aṣọkan <(max-min)/(max+min> | % | ≤ 10% | |

| Epitaixal Wafer Apẹrẹ | Teriba | um | ≤±20 |

| IGBAGBÜ | um | ≤30 | |

| TTV | um | ≤ 10 | |

| LTV | um | ≤2 | |

| Gbogbogbo Abuda | Scratches ipari | mm | ≤30mm |

| Awọn eerun eti | - | KOSI | |

| Itumọ awọn abawọn | ≥97% (Ti a ṣe pẹlu 2*2). Awọn abawọn apaniyan pẹlu: Awọn abawọn pẹlu Micropipe / Awọn ọfin nla, Karooti, onigun mẹta | ||

| Irin idoti | awọn ọta/cm² | d f f l i ≤5E10 awọn ọta/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| Package | Iṣakojọpọ ni pato | pcs / apoti | kasẹti olona-wafer tabi eiyan wafer ẹyọkan |

| 8-inch N-type epitaxial sipesifikesonu | |||

| Paramita | ẹyọkan | Z-MOS | |

| Iru | Condutivity / Dopant | - | N-type / Nitrojini |

| Ifipamọ Layer | Ifipamọ Layer Sisanra | um | 1 |

| Ifarada Layer Sisanra | % | ± 20% | |

| Ifoju Layer Layer | cm-3 | 1.00E + 18 | |

| Ifarada Ifojusi Layer Layer | % | ± 20% | |

| 1st Epi Layer | Epi Layers Sisanra Apapọ | um | 8-12 |

| Isokan Sisanra Awọn Layer Epi (σ/itumọ) | % | ≤2.0 | |

| Ifarada Sisanra Awọn Layer Epi((Spec -Max,min)/Spec) | % | ±6 | |

| Epi Layers Apapọ Doping | cm-3 | 8E+15 ~2E+16 | |

| Aṣọkan Doping Apapọ Epi Layers (σ/tumọ) | % | ≤5 | |

| Ifarada Doping Apapọ Epi Layer ((Spec -Max, | % | ± 10.0 | |

| Epitaixal Wafer Apẹrẹ | Mi )/S) Ijagun | um | ≤50.0 |

| Teriba | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤4.0 (10mm×10mm) | |

| Gbogboogbo Awọn abuda | Scratches | - | Akopọ gigun≤ 1/2 Iwọn ila opin wafer |

| Awọn eerun eti | - | ≤2 eerun, Kọọkan rediosi≤1.5mm | |

| Dada Awọn irin Kontaminesonu | awọn ọta / cm2 | ≤5E10 awọn ọta/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| Ayẹwo Aṣiṣe | % | ≥ 96.0 (Awọn abawọn 2X2 pẹlu Micropipe / Awọn ọfin nla, Karọọti, awọn abawọn onigun mẹta, awọn isubu, Linear/IGSF-s, BPD) | |

| Dada Awọn irin Kontaminesonu | awọn ọta / cm2 | ≤5E10 awọn ọta/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| Package | Iṣakojọpọ ni pato | - | kasẹti olona-wafer tabi eiyan wafer ẹyọkan |

Q1: Kini awọn anfani bọtini ti lilo SiC wafers lori awọn ohun alumọni ohun alumọni ti aṣa ni ẹrọ itanna agbara?

A1:

SiC wafers nfunni ni ọpọlọpọ awọn anfani bọtini lori awọn ohun alumọni ibile (Si) ni ẹrọ itanna agbara, pẹlu:

Ti o ga ṣiṣe: SiC ni bandgap ti o gbooro (3.26 eV) ni akawe si ohun alumọni (1.1 eV), gbigba awọn ẹrọ laaye lati ṣiṣẹ ni awọn foliteji giga, awọn igbohunsafẹfẹ, ati awọn iwọn otutu. Eyi nyorisi isonu agbara kekere ati ṣiṣe ti o ga julọ ni awọn eto iyipada agbara.

Ga Gbona Conductivity: SiC's thermal conductivity jẹ ti o ga julọ ju ti ohun alumọni lọ, ti o mu ki ooru ti o dara julọ ni awọn ohun elo ti o ga julọ, ti o mu ki igbẹkẹle ati igbesi aye awọn ẹrọ agbara.

Ti o ga Foliteji ati lọwọlọwọ mimu: Awọn ẹrọ SiC le mu awọn foliteji ti o ga julọ ati awọn ipele lọwọlọwọ, ṣiṣe wọn dara fun awọn ohun elo agbara-giga gẹgẹbi awọn ọkọ ayọkẹlẹ ina, awọn ọna agbara isọdọtun, ati awọn awakọ ọkọ ayọkẹlẹ ile-iṣẹ.

Iyara Yipada Yiyara: Awọn ẹrọ SiC ni awọn agbara iyipada ti o yarayara, eyi ti o ṣe alabapin si idinku agbara agbara ati iwọn eto, ṣiṣe wọn ni apẹrẹ fun awọn ohun elo igbohunsafẹfẹ giga.

Q2: Kini awọn ohun elo akọkọ ti SiC wafers ni ile-iṣẹ adaṣe?

A2:

Ninu ile-iṣẹ adaṣe, awọn wafers SiC jẹ lilo akọkọ ni:

Electric ti nše ọkọ (EV) Powertrains: SiC-orisun irinše biinvertersatiagbara MOSFETsmu ilọsiwaju ati iṣẹ ṣiṣe ti awọn ọkọ oju-irin ọkọ ina mọnamọna ṣiṣẹ nipasẹ ṣiṣe awọn iyara yiyi yiyara ati iwuwo agbara ti o ga julọ. Eyi nyorisi igbesi aye batiri to gun ati iṣẹ ṣiṣe ọkọ gbogbogbo to dara julọ.

Awọn ṣaja lori-ọkọ: Awọn ẹrọ SiC ṣe iranlọwọ lati mu ilọsiwaju ti awọn ọna ṣiṣe gbigba agbara lori-ọkọ nipa fifun awọn akoko gbigba agbara ni kiakia ati iṣakoso igbona ti o dara julọ, eyiti o ṣe pataki fun awọn EVs lati ṣe atilẹyin awọn ibudo gbigba agbara giga.

Awọn ọna iṣakoso Batiri (BMS): SiC ọna ẹrọ se awọn ṣiṣe tibatiri isakoso awọn ọna šiše, gbigba fun ilana foliteji to dara julọ, mimu agbara ti o ga julọ, ati igbesi aye batiri to gun.

Awọn oluyipada DC-DC: SiC wafers ti wa ni lilo ninuDC-DC converterslati ṣe iyipada agbara DC-giga-giga si agbara DC kekere-kekere daradara siwaju sii, eyiti o ṣe pataki ninu awọn ọkọ ina mọnamọna lati ṣakoso agbara lati batiri si ọpọlọpọ awọn paati ninu ọkọ.

Išẹ ti o ga julọ ti SiC ni giga-foliteji, iwọn otutu giga, ati awọn ohun elo ṣiṣe ti o ga julọ jẹ ki o ṣe pataki fun iyipada ile-iṣẹ ọkọ ayọkẹlẹ si iṣipopada ina.