Ohun elo Tinrin Wafer fun 4 Inch-12 Inch Sapphire/SiC/Si Wafers Ṣiṣe

Ilana Ṣiṣẹ

Ilana tinrin wafer nṣiṣẹ nipasẹ awọn ipele mẹta:

Lilọ ti o ni inira: Kẹkẹ diamond kan (iwọn grit 200-500 μm) yọ 50-150 μm ti ohun elo kuro ni 3000-5000 rpm lati dinku sisanra ni kiakia.

Lilọ Didara: Kẹkẹ ti o dara julọ (iwọn grit 1–50 μm) dinku sisanra si 20–50 μm ni <1 μm/s lati dinku ibajẹ abẹlẹ.

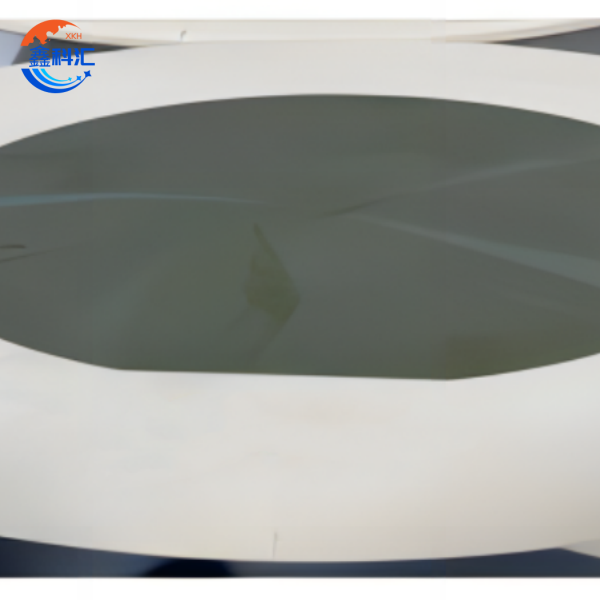

Polishing (CMP): Atọka-kemikali-ẹrọ n yọkuro ibajẹ ti o ku, iyọrisi Ra <0.1 nm.

Awọn ohun elo ibaramu

Ohun alumọni (Si): Standard fun CMOS wafers, tinrin si 25 μm fun 3D akopọ.

Silicon Carbide (SiC): Nilo awọn kẹkẹ okuta iyebiye pataki (80% ifọkansi diamond) fun iduroṣinṣin gbona.

Sapphire (Al₂O₃): Tinrin si 50 μm fun awọn ohun elo LED UV.

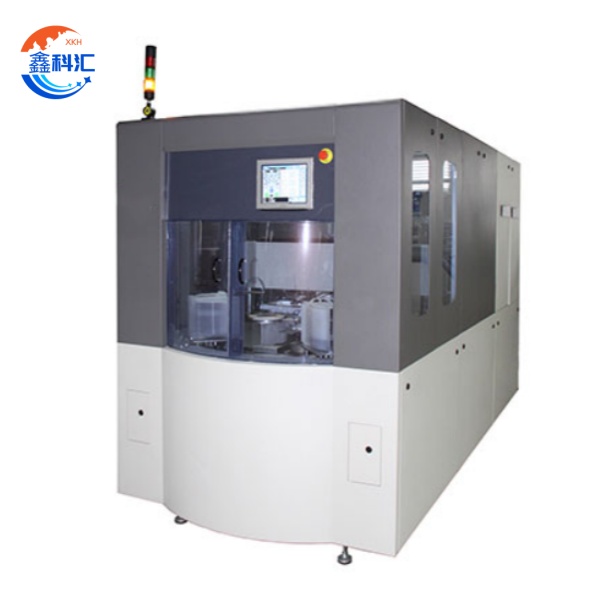

Mojuto System irinše

1. Eto lilọ

Grinder-Axis Meji: Darapọ isokuso / lilọ ti o dara ni pẹpẹ kan, idinku akoko iyipo nipasẹ 40%.

Spindle Aerostatic: Iwọn iyara 0-6000 rpm pẹlu <0.5 μm radial runout.

2. Eto mimu Wafer

Chuck Vacuum:> 50 N dani agbara pẹlu deede ipo ipo ± 0.1 μm.

Apa Robotik: Gbigbe 4-12-inch wafers ni 100 mm/s.

3. Eto Iṣakoso

Interferometry lesa: Abojuto sisanra akoko gidi (ipinnu 0.01 μm).

Ifunni-iwakọ AI: Awọn asọtẹlẹ wiwọ kẹkẹ ati ṣatunṣe awọn ayeraye laifọwọyi.

4. Itutu & Cleaning

Ultrasonic Cleaning: Yọ awọn patikulu> 0.5 μm pẹlu ṣiṣe 99.9%.

Omi Deionized: Tutu wafer si <5°C loke ibaramu.

Awọn anfani pataki

1. Ultra-High Precision: TTV (Lapapọ Iyatọ Sisanra) <0.5 μm, WTW (Laarin-Wafer Iyatọ Sisanra) <1 μm.

2. Isopọpọ-ilana pupọ: Darapọ lilọ, CMP, ati etching pilasima ninu ẹrọ kan.

3. Ibamu Ohun elo:

Ohun alumọni: Idinku sisanra lati 775 μm si 25 μm.

SiC: Ṣe aṣeyọri <2 μm TTV fun awọn ohun elo RF.

Awọn Wafers Doped: Fọsifọọsi-doped InP wafers pẹlu <5% fiseete resistivity.

4. Automation Smart: Isopọpọ MES dinku aṣiṣe eniyan nipasẹ 70%.

5. Ṣiṣe Agbara: 30% agbara agbara kekere nipasẹ idaduro atunṣe.

Awọn ohun elo bọtini

1. Iṣakojọpọ ilọsiwaju

• Awọn ICs 3D: Tinrin Wafer jẹ ki iṣakojọpọ inaro ti ọgbọn / awọn eerun iranti (fun apẹẹrẹ, awọn akopọ HBM), iyọrisi bandiwidi giga giga 10 × ati 50% idinku agbara agbara ni akawe si awọn ojutu 2.5D. Ohun elo naa ṣe atilẹyin isọpọ arabara ati isọpọ TSV (Nipasẹ-Silicon Via), pataki fun awọn ilana AI / ML ti o nilo <10 μm interconnect pitch. Fun apẹẹrẹ, 12-inch wafers tinrin si 25 μm ngbanilaaye iṣakojọpọ awọn fẹlẹfẹlẹ 8+ lakoko ti o n ṣetọju <1.5% oju-iwe ogun, pataki fun awọn eto LiDAR adaṣe.

• Iṣakojọpọ Fan-Jade: Nipa didin sisanra wafer si 30 μm, ipari asopọ asopọ ti kuru nipasẹ 50%, idinku idaduro ifihan agbara (<0.2 ps/mm) ati mimuuṣe awọn chiplets 0.4 mm olekenka-tinrin fun awọn SoC alagbeka. Ilana naa n mu awọn algoridimu ti o ni isanpada wahala lati ṣe idiwọ oju-iwe ogun (> 50 μm TTV iṣakoso), ni idaniloju igbẹkẹle ninu awọn ohun elo RF igbohunsafẹfẹ giga.

2. Awọn ẹrọ itanna agbara

• Awọn Modulu IGBT: Tinrin si 50 μm dinku resistance igbona si <0.5 ° C / W, ṣiṣe awọn 1200V SiC MOSFETs lati ṣiṣẹ ni awọn iwọn 200 ° C junction. Ohun elo wa nlo lilọ-ipele pupọ (isọdi: 46 μm grit → itanran: 4 μm grit) lati yọkuro ibajẹ abẹlẹ, iyọrisi> awọn akoko 10,000 ti igbẹkẹle gigun kẹkẹ gbona. Eyi ṣe pataki fun awọn oluyipada EV, nibiti 10 μm-nipọn SiC wafers ṣe ilọsiwaju iyara iyipada nipasẹ 30% .

• Awọn ẹrọ Agbara GaN-on-SiC: Wafer tinrin si 80 μm nmu ilọsiwaju elekitironi pọ si (μ> 2000 cm²/V·s) fun 650V GaN HEMTs, idinku awọn adanu idari nipasẹ 18%. Ilana naa nlo dicing-iranlọwọ lesa lati ṣe idiwọ sisan lakoko tinrin, ṣiṣe iyọrisi <5 μm eti chipping fun awọn ampilifaya agbara RF.

3. Optoelectronics

• Awọn LED GaN-on-SiC: Awọn sobusitireti sapphire 50 μm ṣe ilọsiwaju imudara isediwon ina (LEE) si 85% (vs. 65% fun 150 μm wafers) nipa didindinku idẹkùn photon. Iṣakoso TTV ultra-kekere ti ohun elo wa (<0.3 μm) ṣe idaniloju itujade LED aṣọ kọja awọn wafers 12-inch, pataki fun awọn ifihan Micro-LED ti o nilo isokan gigun gigun <100nm.

• Silikoni Photonics: 25μm-nipọn silikoni wafers jeki 3 dB / cm kekere soju pipadanu ni waveguides, pataki fun 1.6 Tbps opitika transceivers. Ilana naa ṣopọ sisẹ CMP lati dinku aibikita dada si Ra <0.1 nm, imudara imudara idapọmọra nipasẹ 40%.

4. Awọn sensọ MEMS

• Accelerometers: 25 μm silicon wafers ṣe aṣeyọri SNR> 85 dB (vs. 75 dB fun 50 μm wafers) nipa jijẹ ifamọ iṣipopada ibi-ẹri. Eto lilọ-aksi meji wa sanpada fun awọn iwọn aapọn, ni idaniloju <0.5% fifo ifamọ lori -40°C si 125°C. Awọn ohun elo pẹlu wiwa jamba ọkọ ayọkẹlẹ ati ipasẹ išipopada AR/VR.

• Awọn sensọ Titẹ: Tinrin si 40 μm jẹ ki awọn sakani wiwọn 0-300 bar pẹlu <0.1% FS hysteresis. Lilo isunmọ igba diẹ (awọn gbigbe gilasi), ilana naa yago fun fifọ wafer lakoko etching ẹhin, ṣiṣe iyọrisi ifarada iwọn 1 μm fun awọn sensọ IoT ile-iṣẹ.

• Amuṣiṣẹpọ Imọ-ẹrọ: Awọn ohun elo tinrin wafer ṣe iṣọkan lilọ ẹrọ, CMP, ati pilasima etching lati koju awọn italaya ohun elo oniruuru (Si, SiC, Sapphire). Fun apẹẹrẹ, GaN-on-SiC nilo lilọ arabara (awọn kẹkẹ diamond + pilasima) lati ṣe iwọntunwọnsi líle ati imugboroosi gbona, lakoko ti awọn sensosi MEMS beere fun iha ilẹ-5 nm aibikita nipasẹ didan CMP.

• Ipa ile-iṣẹ: Nipa fifun awọn tinrin, awọn wafers ti o ga julọ, imọ-ẹrọ yii n ṣe awọn imotuntun ni awọn eerun AI, awọn modulu 5G mmWave, ati awọn ẹrọ itanna ti o rọ, pẹlu awọn ifarada TTV <0.1 μm fun awọn ifihan foldable ati <0.5 μm fun awọn sensọ LiDAR adaṣe.

Awọn iṣẹ XKH

1. Awọn solusan adani

Awọn atunto iwọn: Awọn apẹrẹ iyẹwu 4-12-inch pẹlu ikojọpọ adaṣe adaṣe.

Atilẹyin Doping: Awọn ilana aṣa fun awọn kirisita Er/Yb-doped ati awọn wafers InP/GaAs.

2. Ipari-si-Ipari Atilẹyin

Idagbasoke Ilana: Idanwo ọfẹ n ṣiṣẹ pẹlu iṣapeye.

Ikẹkọ Agbaye: Awọn idanileko imọ-ẹrọ lododun lori itọju ati laasigbotitusita.

3. Ṣiṣẹpọ Ohun elo lọpọlọpọ

SiC: Wafer tinrin si 100 μm pẹlu Ra <0.1 nm.

Sapphire: sisanra 50μm fun awọn ferese laser UV (gbigbe> 92% @ 200 nm).

4. Awọn iṣẹ afikun-iye

Ipese Lilo: Awọn kẹkẹ Diamond (2000+ wafers / igbesi aye) ati awọn slurries CMP.

Ipari

Ohun elo tinrin wafer yii n ṣe jiṣẹ deede ti ile-iṣẹ, iṣipopada ohun elo pupọ, ati adaṣe adaṣe, ti o jẹ ki o ṣe pataki fun isọpọ 3D ati ẹrọ itanna agbara. Awọn iṣẹ okeerẹ XKH - lati isọdi si iṣelọpọ lẹhin-ṣe rii daju pe awọn alabara ṣaṣeyọri ṣiṣe idiyele ati didara julọ iṣẹ ni iṣelọpọ semikondokito.